As a professional manufacturer, Yadaworks offer three different enclosure & housings solutions that can all be customized to meet your individual requirements, including: machined from solid block; or formed from sheet metal; or use a combination of extrusions, sheet metal top and bottom, and custom machined panels.

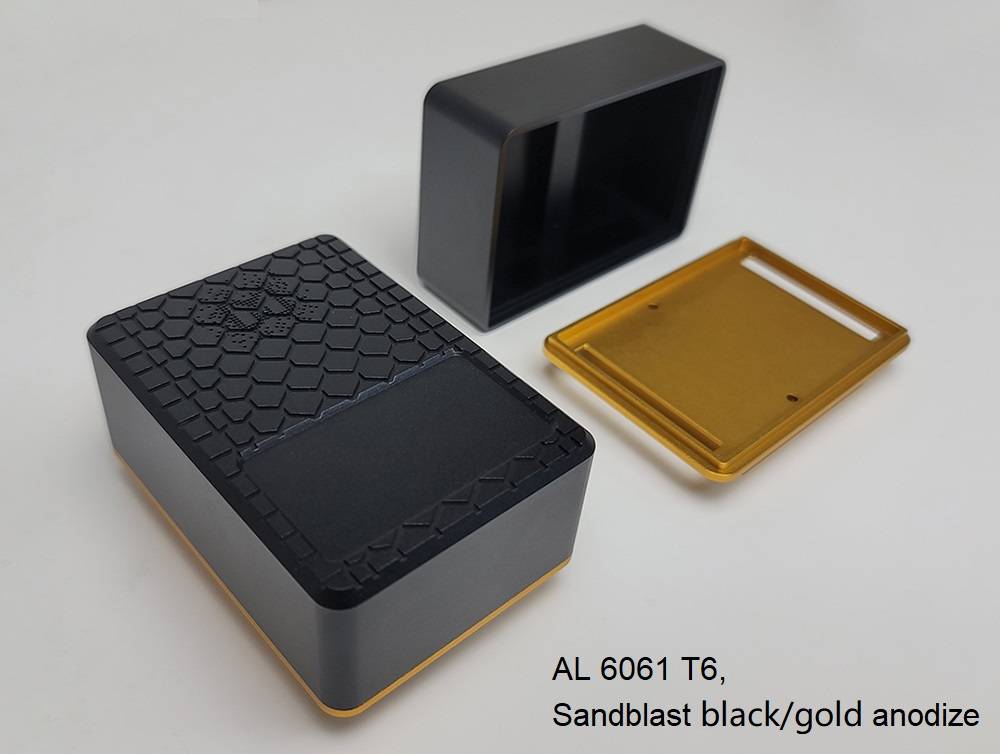

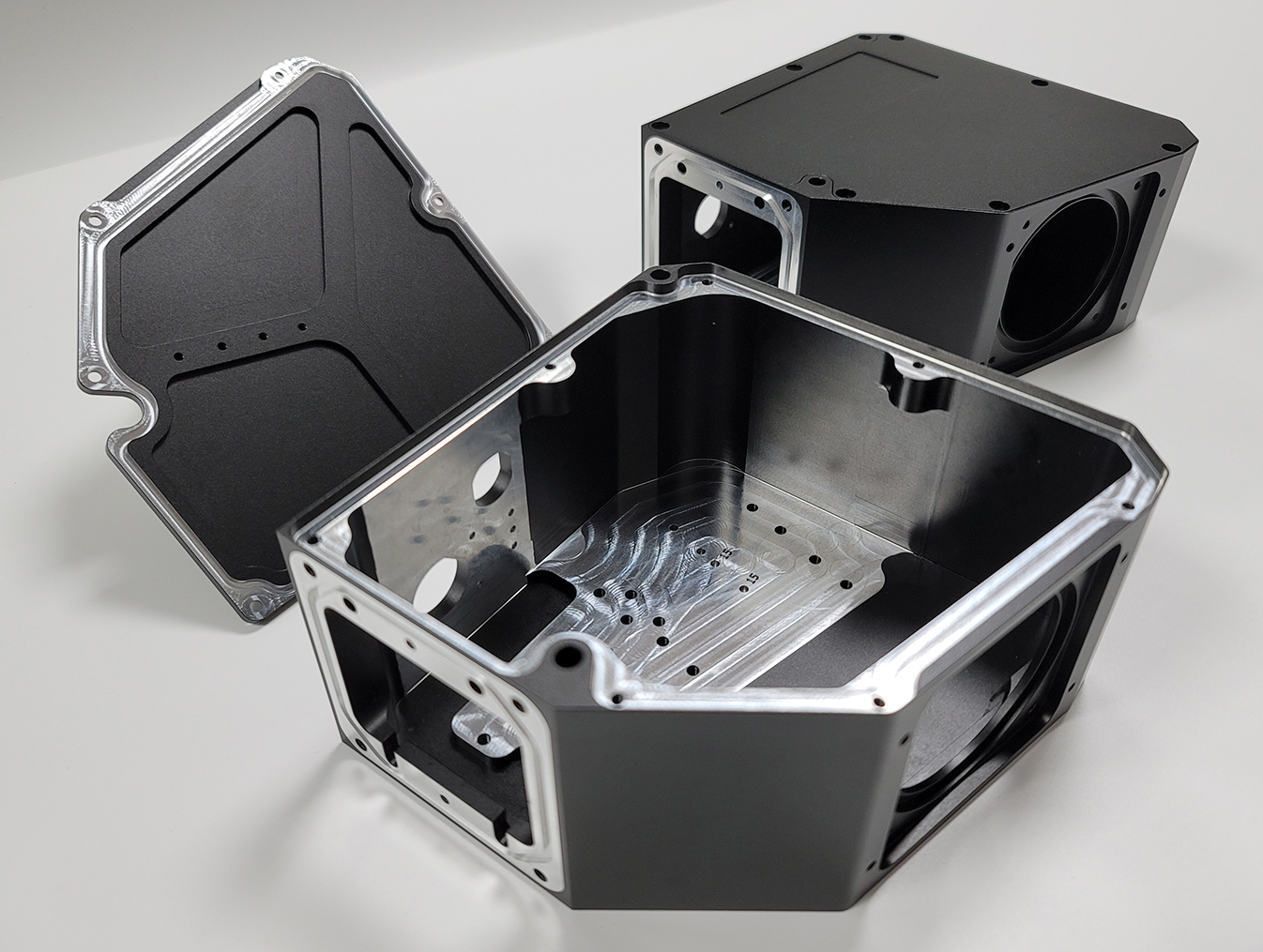

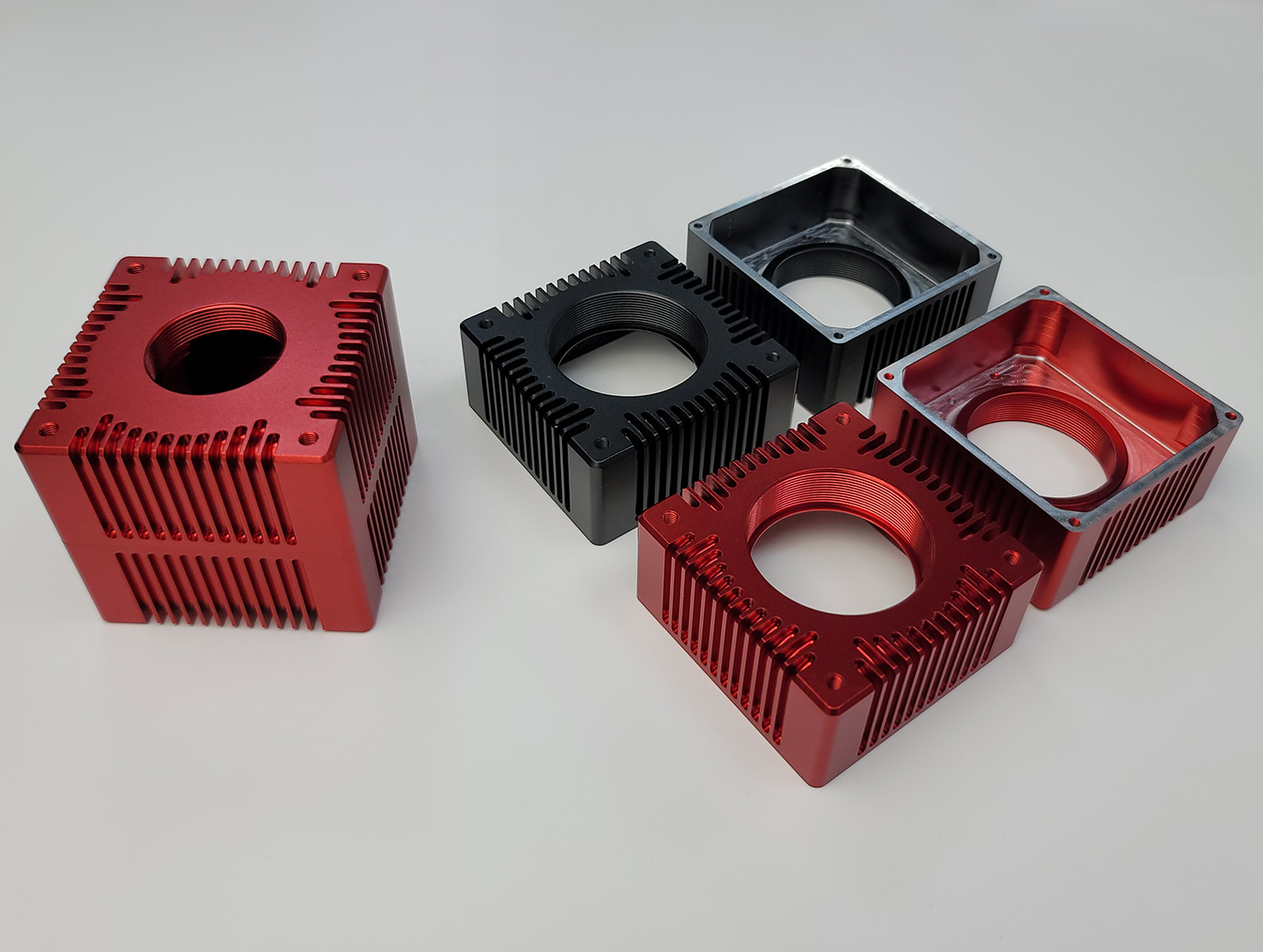

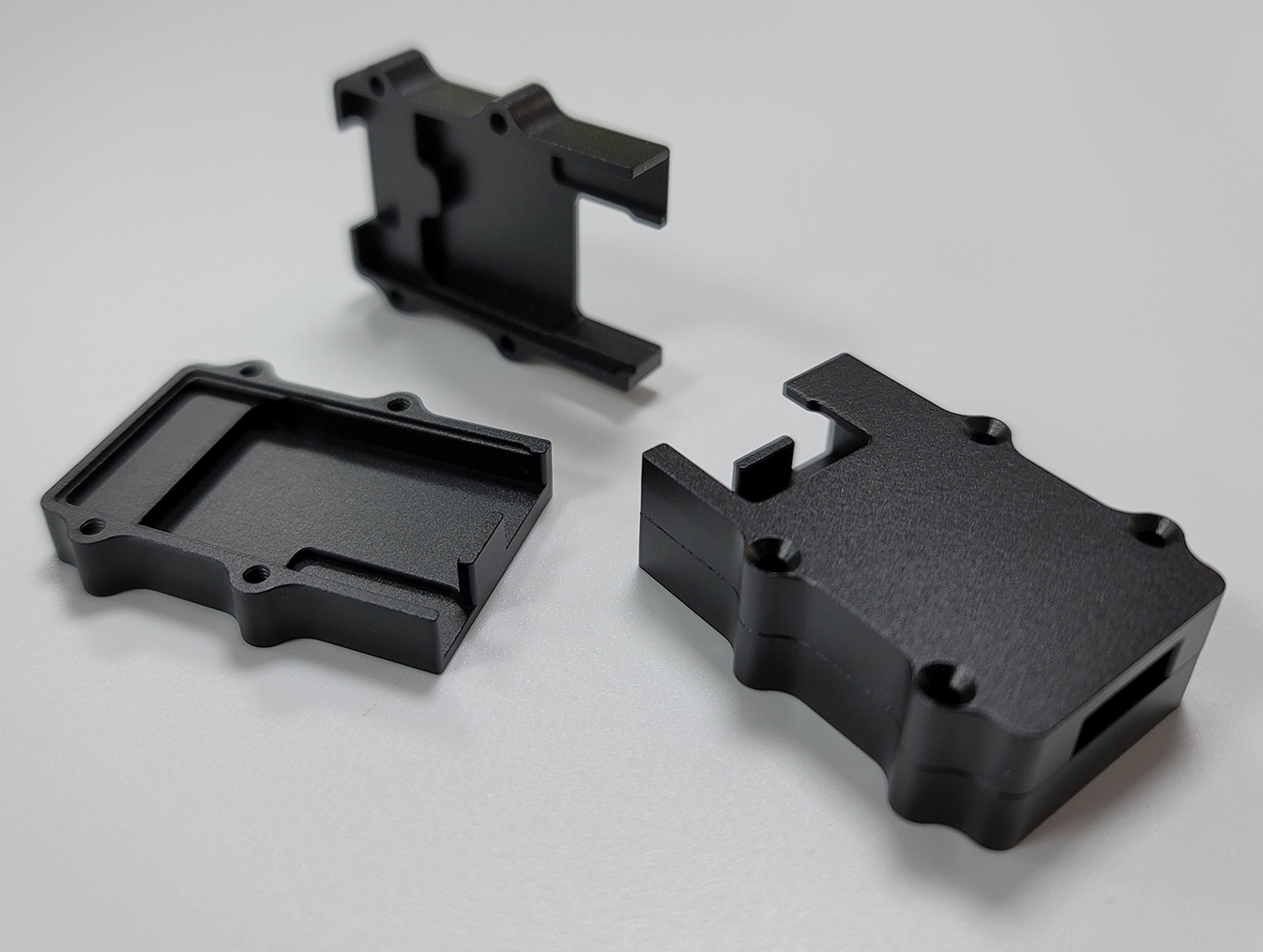

Machined Enclosures & Housings

Sheet Metal Enclosures

Hybrid Enclosures

Available Material For Custom Enclosures & Housings

Yadaworks provide different materials enclosures & housings solutions

in aluminium, steel, plastic or Titanium to fit your needs.

Aluminum enclosures & housings has a high heat tolerance and corrosion-resistant, and provides a natural level of RFI/EMI shielding. Our manufacturing service team use aluminum blocks, extrusions and sheet to create high quality aluminum enclosures for a wide variety of electronics equipment and applications.

Steel is an iron alloy, meaning it’s primarily composed of iron. It offers a good combination of cost and structural integrity (stiffness). Steel enclosures are resistant to fire and corrosion. The enclosures can withstand extreme environmental conditions, like extreme hot and wet climates.

Plastic enclosures & housings are the most popular and economical way to protect electronic devices from any adverse effects. Often electrical enclosure manufacturers choose aluminum and steel for their enclosures,for most of the items you can save a lot of money by using plastic. Furthermore, used in the right conditions, plastic enclosures tend to last longer than those created from other materials.

Titanium enclosures are widely used in medical, automobile industry because of its light weight, high strength and good corrosion resistance.

Featured Enclosure Categories

Range from square to round, from simple to complex and

from waterproof electrical enclosures to basic cases.

Custom Enclosures & Housings FAQs

Get the support you need on Custom Enclosures & Housings and engineering information by reading the FAQ here.

We typically make transparent enclosures & housings with materials such as acrylic. We also are able to install transparent plastic windows onto your custom enclosures upon request.

We manufacture custom enclosures & housings, mounting hardware, and miscellaneous components. We start from your design, and usually build them in 7-21 days, depending on its complexity.

The standard tolerance on variation of size and position of cutouts and profiles is +/-0.10mm. If you have special request, please contact us.

An electronics enclosure often needs a cooling capacity as well. Integrating the heatsink into the enclosure is not a problem for us there. We can make heatsink enclosures by milling exactly according to you specifications.

Hybrid enclosure is a combination process of extrusions, sheet metal top and bottom, and custom machined panels and body. Extrusion, Sheet metal and CNC machining processes have unique strengths and weaknesses attributed to both. The machined body made of blocks can provide durable and long-lasting housing. while, you can save your money through using extrusions and sheet metal.without wasted time, materials or labor, driving costs down in the process.

Yadaworks offer three different enclosure & housings solutions that can all be customized to meet your individual requirements, including: machined from solid block; or formed from sheet metal; or use a combination of extrusions, sheet metal top and bottom, and custom machined panels.