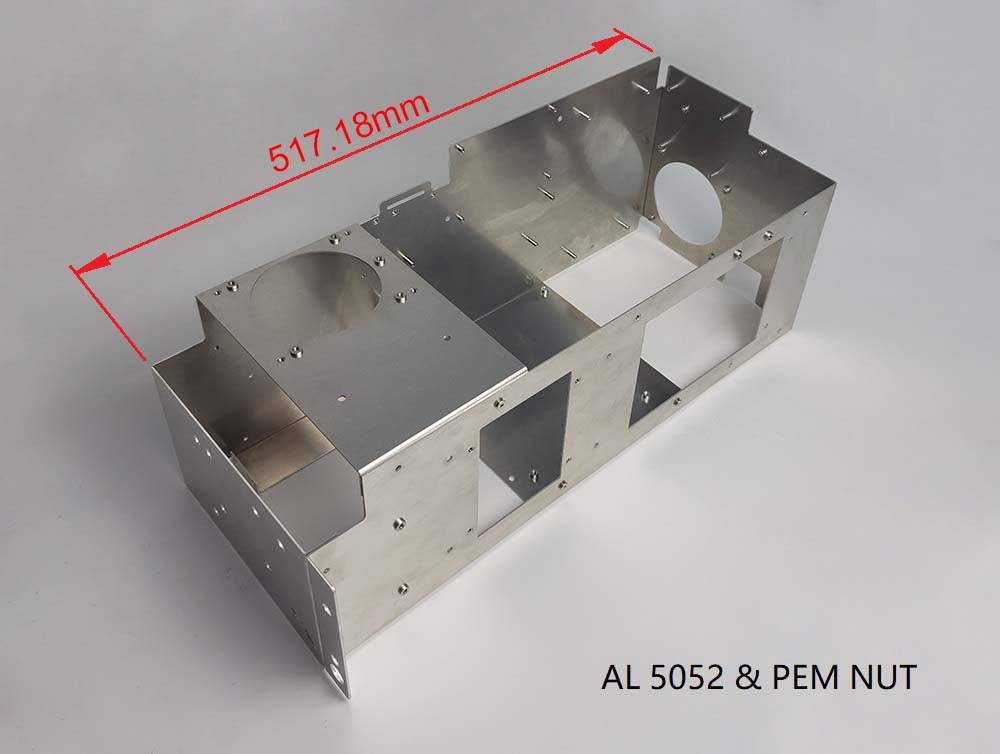

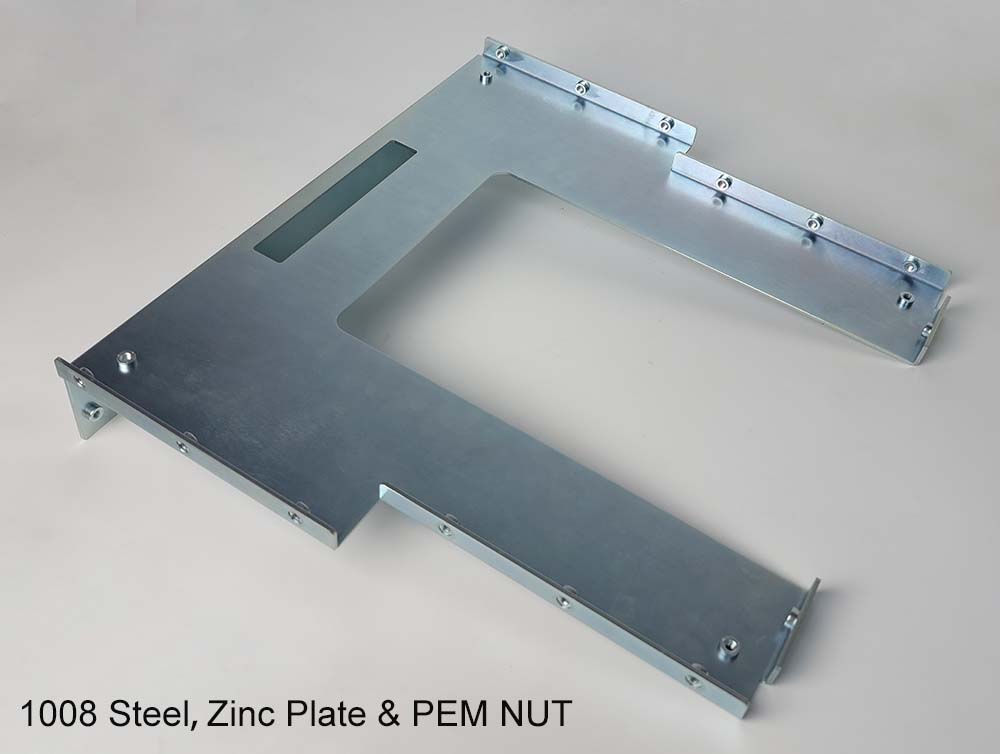

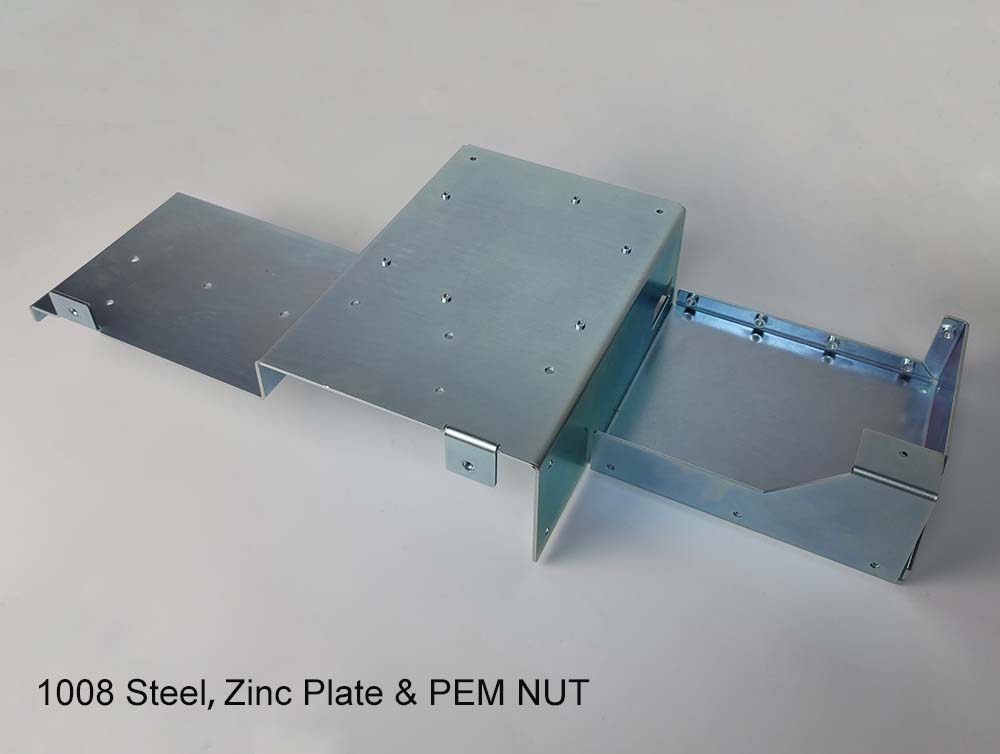

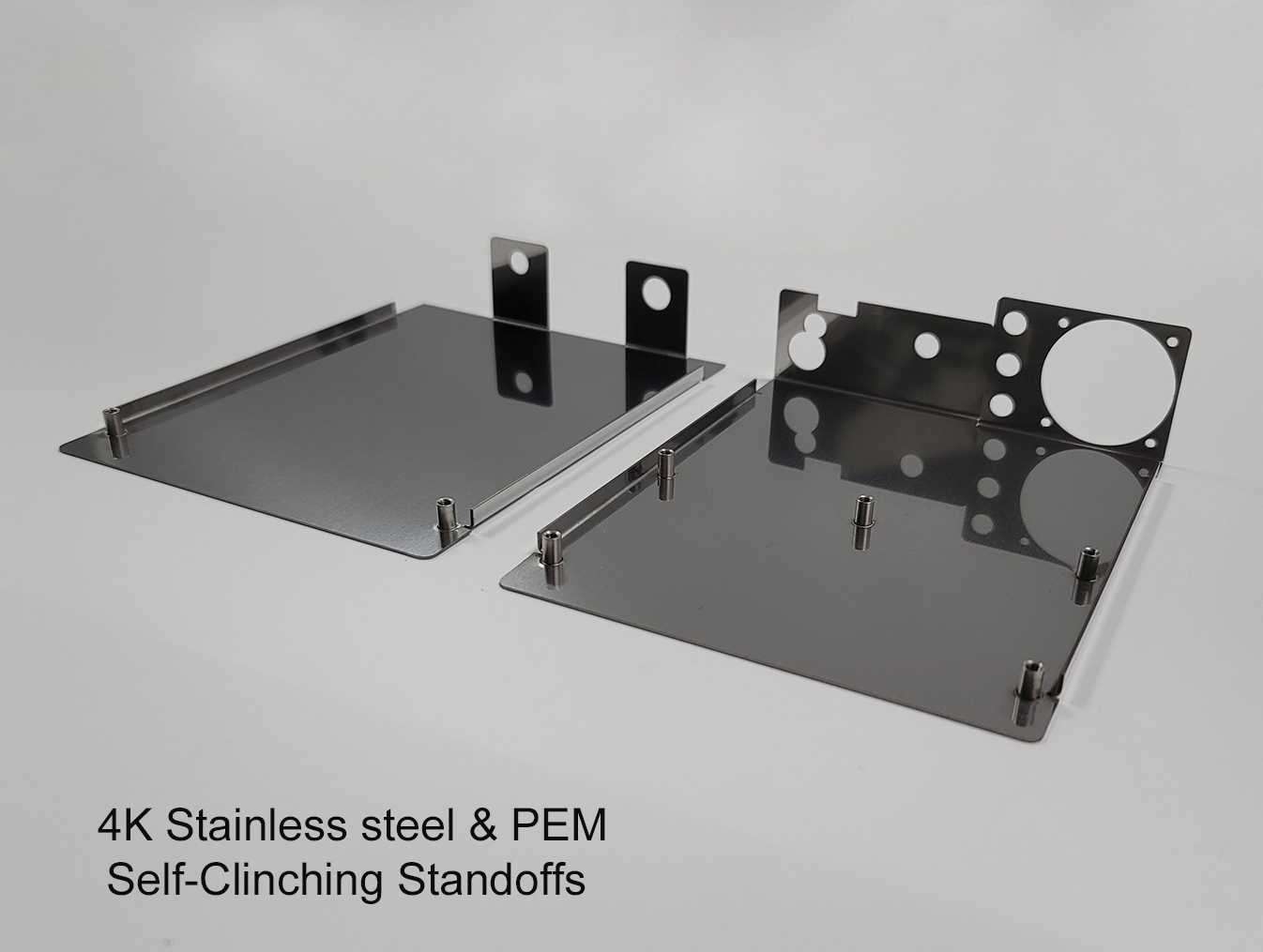

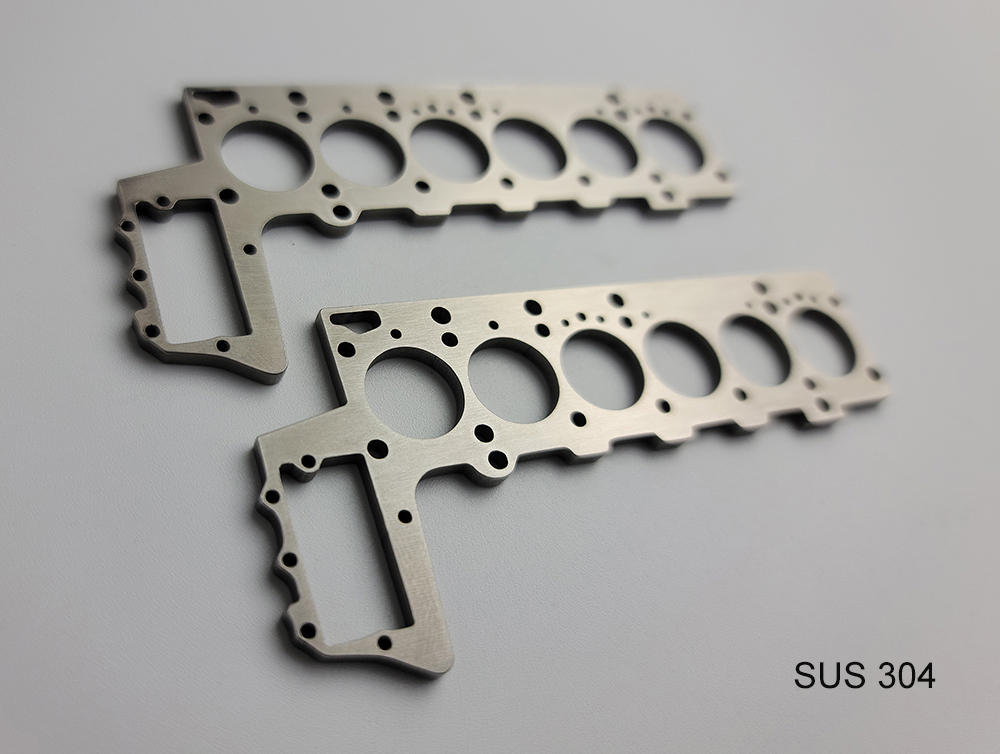

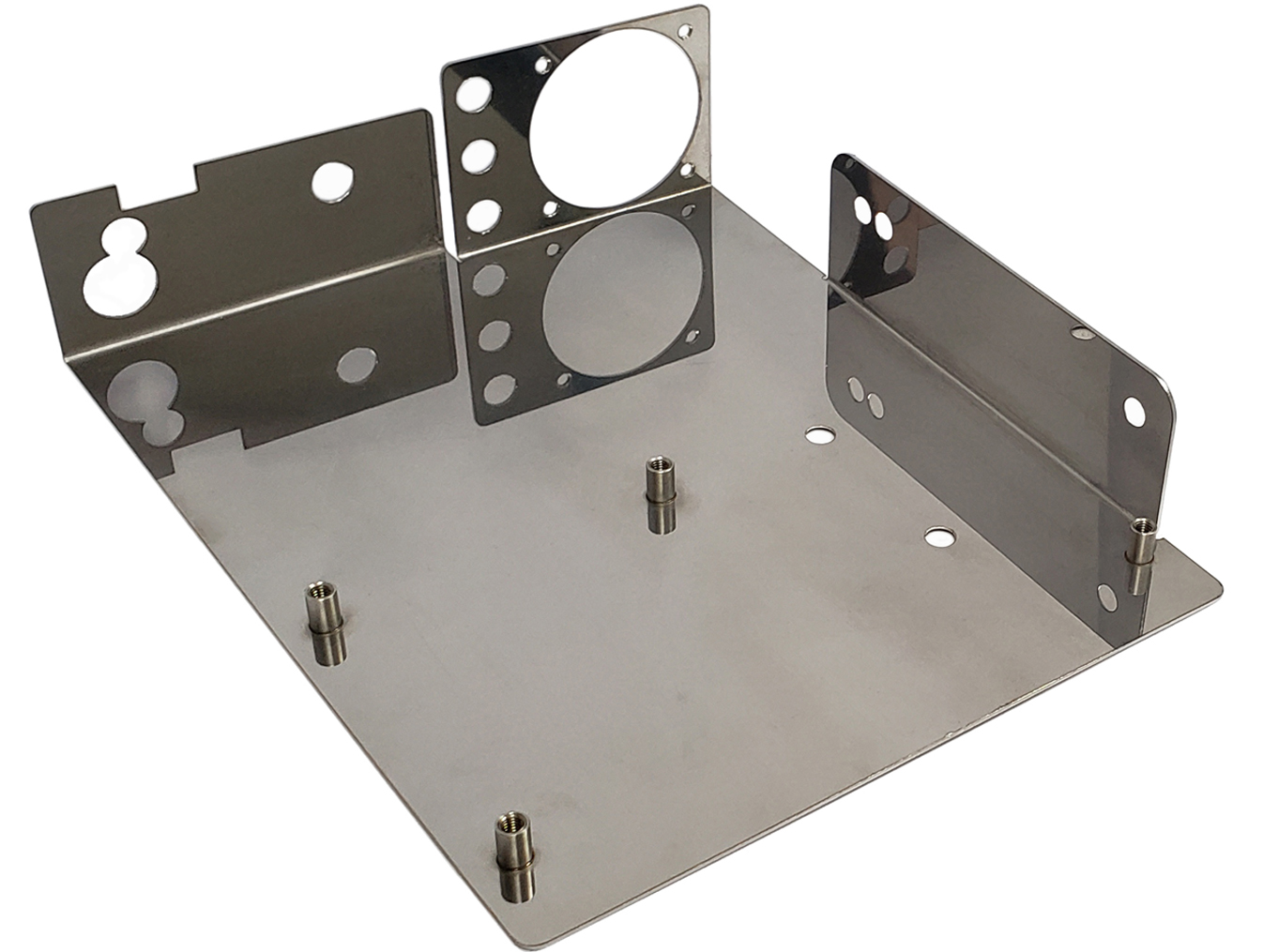

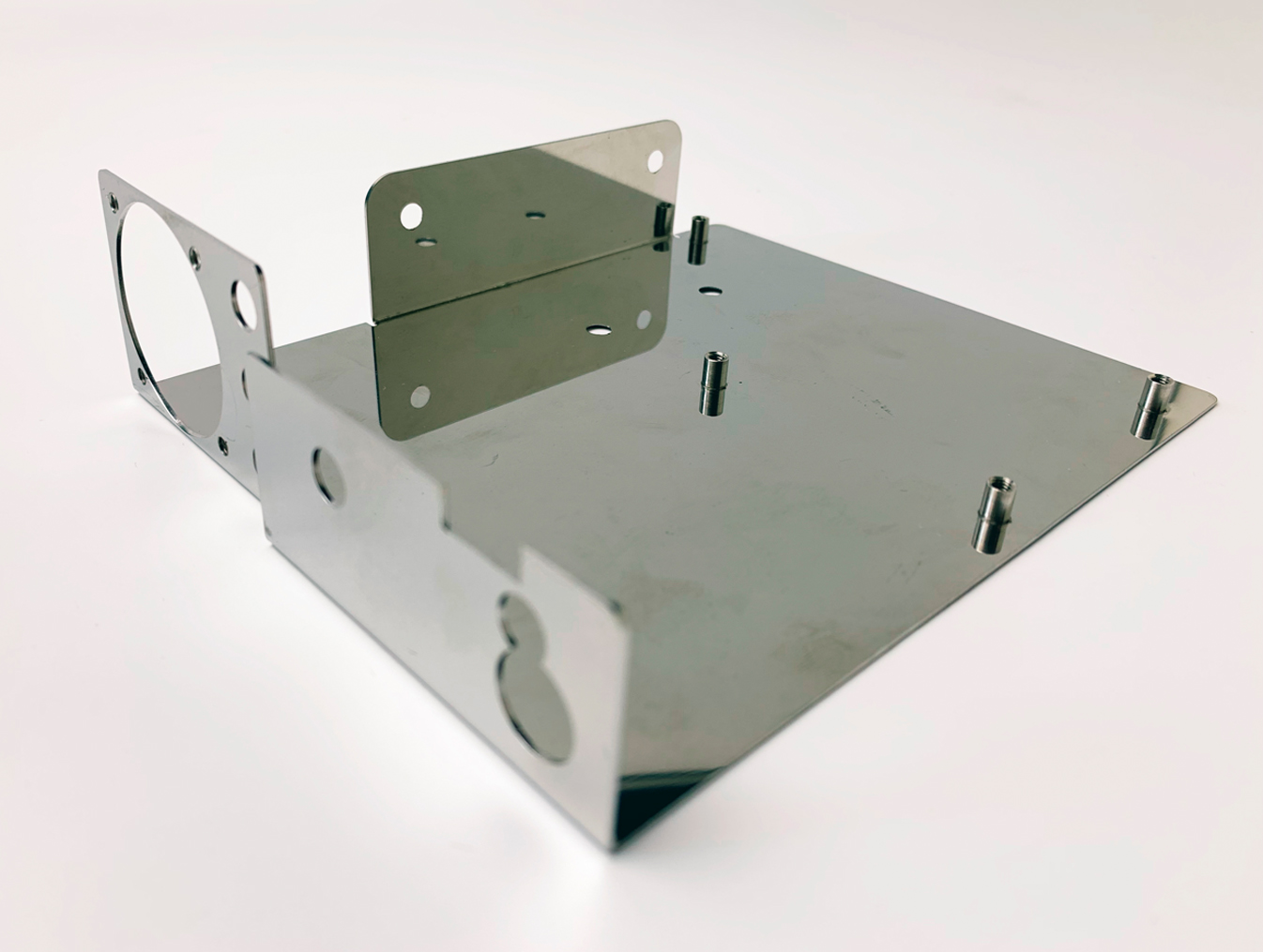

Yadaworks manufactures custom sheet metal parts, such as brackets, plates, frames, arms, fixtures and more, in 3-4 days, with absolutely no minimum order.

Unlike traditional sheet metal shops, YADAWORKS custom sheet metal fabrication uses a range of process including laser cutting, bending, punching, welding services, combined with CNC machining technology,provide you with the precision parts needed from prototype to mass production.

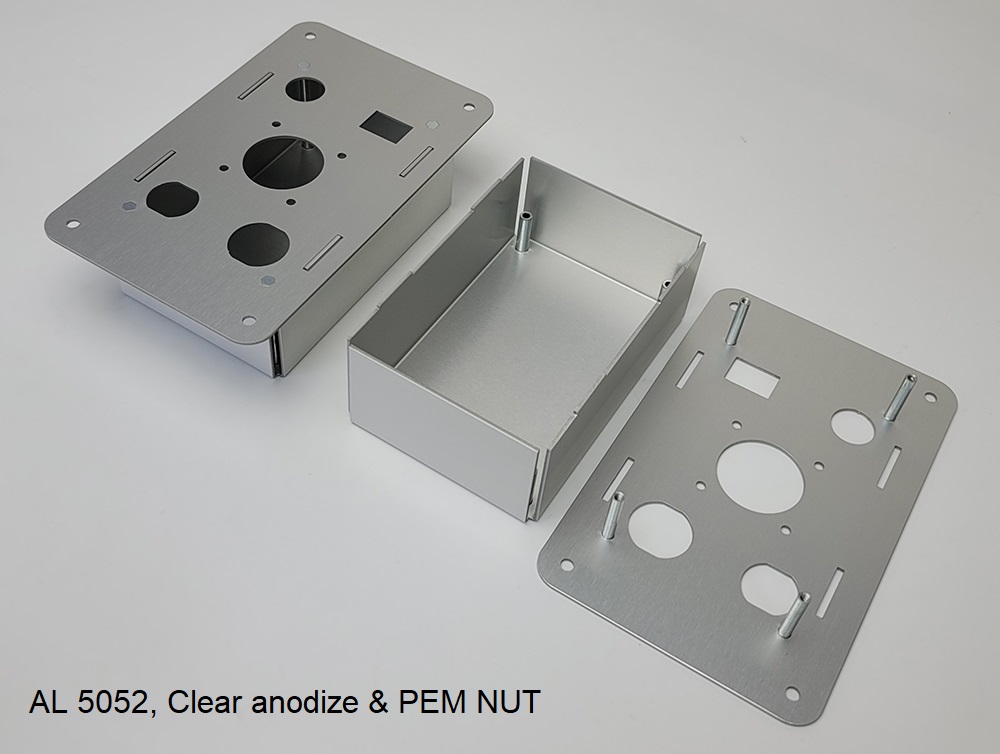

Our sheet metal fabrication is also a one-stop source for custom,fully finished precision sheet metal parts.Choose from a variety of materials,hardware,fasteners,and rich colors to fully finish your custom sheet metal part.

Available Material For Sheet Metal Fabrication

Here is a list of our standard sheet metal materials available:

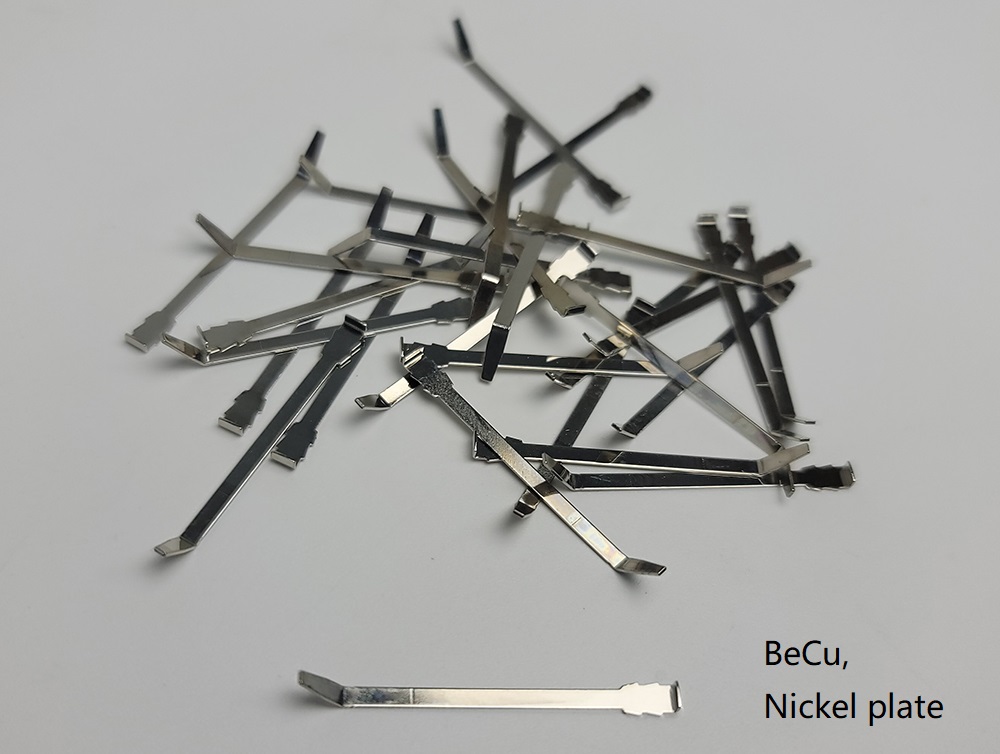

Aluminum is a highly ductile metal, corrosion resistant, light weight and making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Brass has excellent electrical conductivity along with exceptional formability, and is thus ideally suited for electrical and electronic applications.

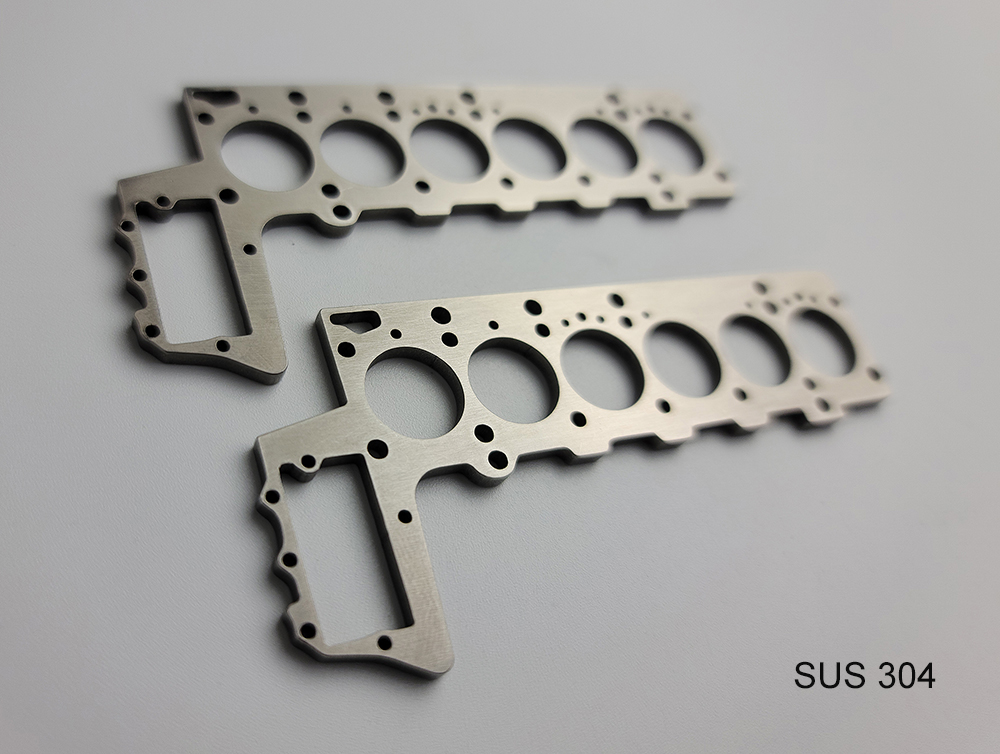

Stainless steel has Same stiffness advantage of steel yet even higher strength.features a high-temperature resistant, with good oxidation resistance and corrosion resistance.

Steel is an iron alloy, meaning it’s primarily composed of iron. It offers a good combination of cost and structural integrity (stiffness).

Titanium is a hard metal, but the best steels are generally stronger than titanium alloys.but titanium has the ability to flex or bow repeatedly.Titanium alloy is widely used in medical, automobile industry because of its light weight, high strength and good corrosion resistance.

Available Surface Finishes of Our Sheet Metal Fabrication

At Yadaworks, in Addition to Precision,

you can get sheet metal parts with nice surface and more option