What is surface finishing?

Surface finishing makes the difference between a quality product and a bargain-bin reject.

There are many surface finishing processes available to manufacturers. Each has its strengths, weaknesses, and peculiar quirks.which all improve the aesthetic appearance, material strength, and other properties of the finished product. They work by adding, altering, removing, or reshaping the material. These processes are usually achieved through mechanical, chemical, or electrical means.Depending on your application's requirements, Yadaworks can provide the following finishing options for our CNC machined Panels, Enclosures and Parts:

Yadaworks standard surface texture

Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding, polishing, tumbling, blasting, honing, milling, or other processes.

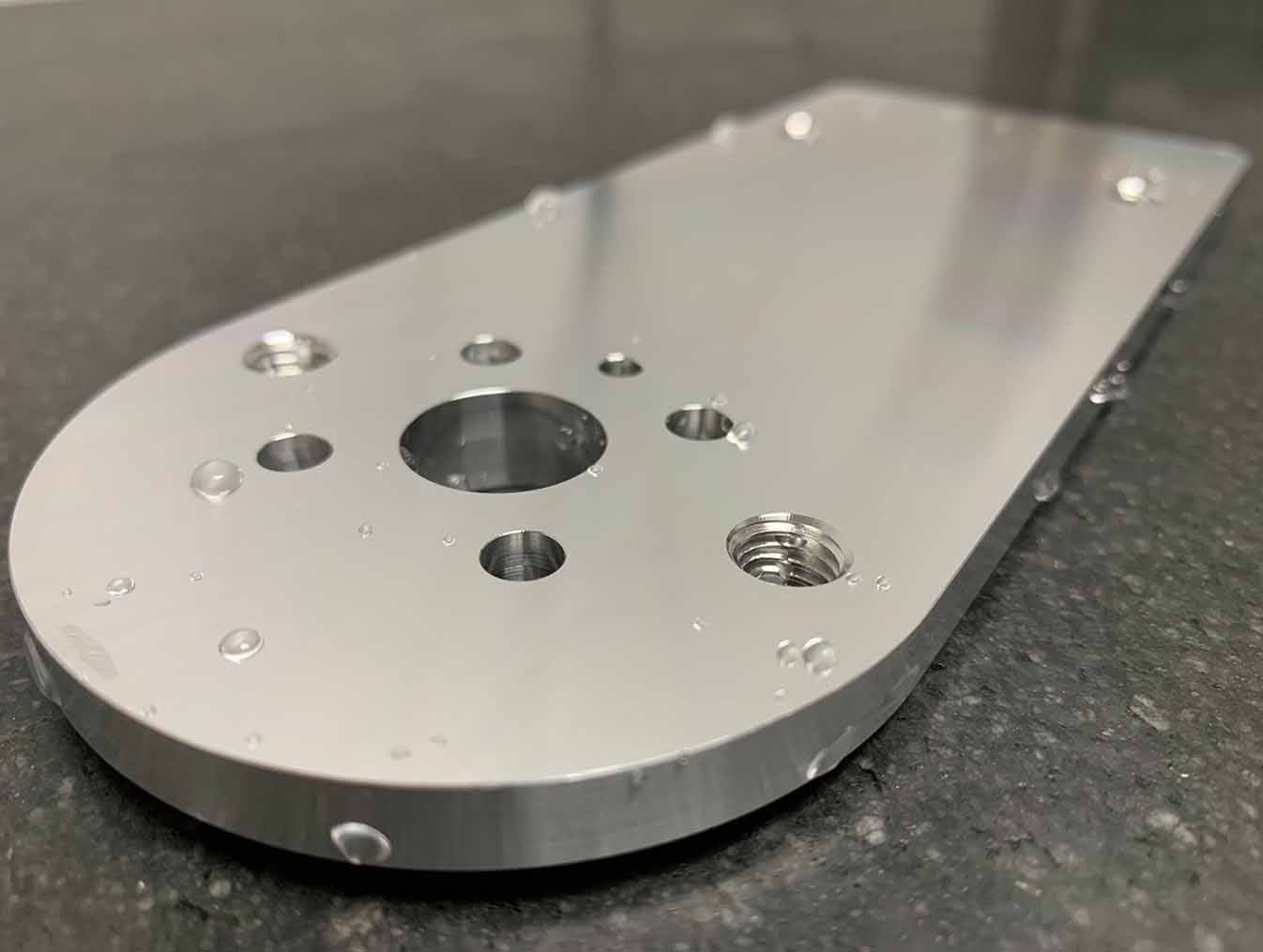

Machined

Surface roughness of Ra 1.6 μm

Visible tool marks

Smooth Machined

Surface roughness of Ra 1.0 μm

Less tool marks

Tumbled

Uniform matte

Removing the tool marks

Polished

Surface roughness of Ra 0.8 μm

Less or no visible tool marks

Sandblasted

Grit #80 - 220

Uniform matte or satin surface

Removing the tool marks

Brushed

Grit #400 - 800

Surface roughness of Ra 1.2 μm

Visible tool marks

Yadaworks surface finishing capabilities

Surface finishing may be defined as any process that alters the surface of a material or aesthetic or functional purposes.The basis material can be a steel, a aluminum, a plastic and any material used for engineering or decorative purposes.

Surface finishing can hide any number of faults in a machined part, but there are limits. Surface finishing can improve the aesthetic appeal of a machined part by changing its gloss, hininess and colour, can improve corrosion resistance and tailor surface properties. Yadaworks provides the following surface finishing:

Clear anodizing is used on almost all consumer products made of aluminum-- without it, the metal would become dull from exposure to oxygen, moisture, and environmental chemicals. A clear anodized surface looks glazed or very subtly grainy compared to a bare polished aluminum surface.

Hard anodizing is used to increase the wear and corrosion resistance, increase the surface hardness, and improve the thermal and dialectical properties of treated aluminum objects. Our standard oxide layers are generally 25 to 40 μm thick—with Type III anodizing, this layer can be increased up to 100 μm* (0.004”).

Chromate conversion coating, more commonly known as chem film or by its brand name Alodine, is a chemical coating that passivates and protects aluminum from corrosion. We offer two types of chemical conversion: Type I – Yellow finish and colors range from light yellow to brown. Type II – Transparent finish.

Black oxide is a conversion coating that is used for appearance and to add mild corrosion resistance and minimize light reflection. It is used for ferrous materials, zinc, copper and its alloys, silver solder and powdered metals. Black oxides are used where component accuracy and tolerance are paramount.

Parts are bead blasted and then anodized. Ideal for increasing the corrosion resistance of the part, the adhesion between it and the coating, prolonging the durability of the coating.

Brushed anodize finish resists scratching, and requires minimal maintenance including in high-traffic areas offering excellent wear and abrasion resistance.Without diminishing the anodize finish’s performance, our "brushed” aesthetic option is gaining interest for aluminum products.

Color anodizing is a popular process because it allows for the creation of products in a wide range of colors, Including red, black, blue, green, golden, pink, purple, champagne, even two-colors. Such an enhancement of appearance can make a product more appealing to a potential customer.

Electroless nickel plating are used to provide protection from wear and abrasion, resistance against corrosion, and add hardness to parts of all conditions. It’s commonly used in coatings applications in engineering, aerospace, oil and gas, construction, electronics and several others.

Electroplating is the process of using electrodeposition to coat an object in a layer of metal(s). You can electroplate a single metal onto an object, or a combination of metals, Substrates can be made of almost any material, from stainless steel and other metals to plastics. Materials commonly used in electroplating include:Brass, Chromium, Copper, Gold, Nickel, Silver, Zinc etc.

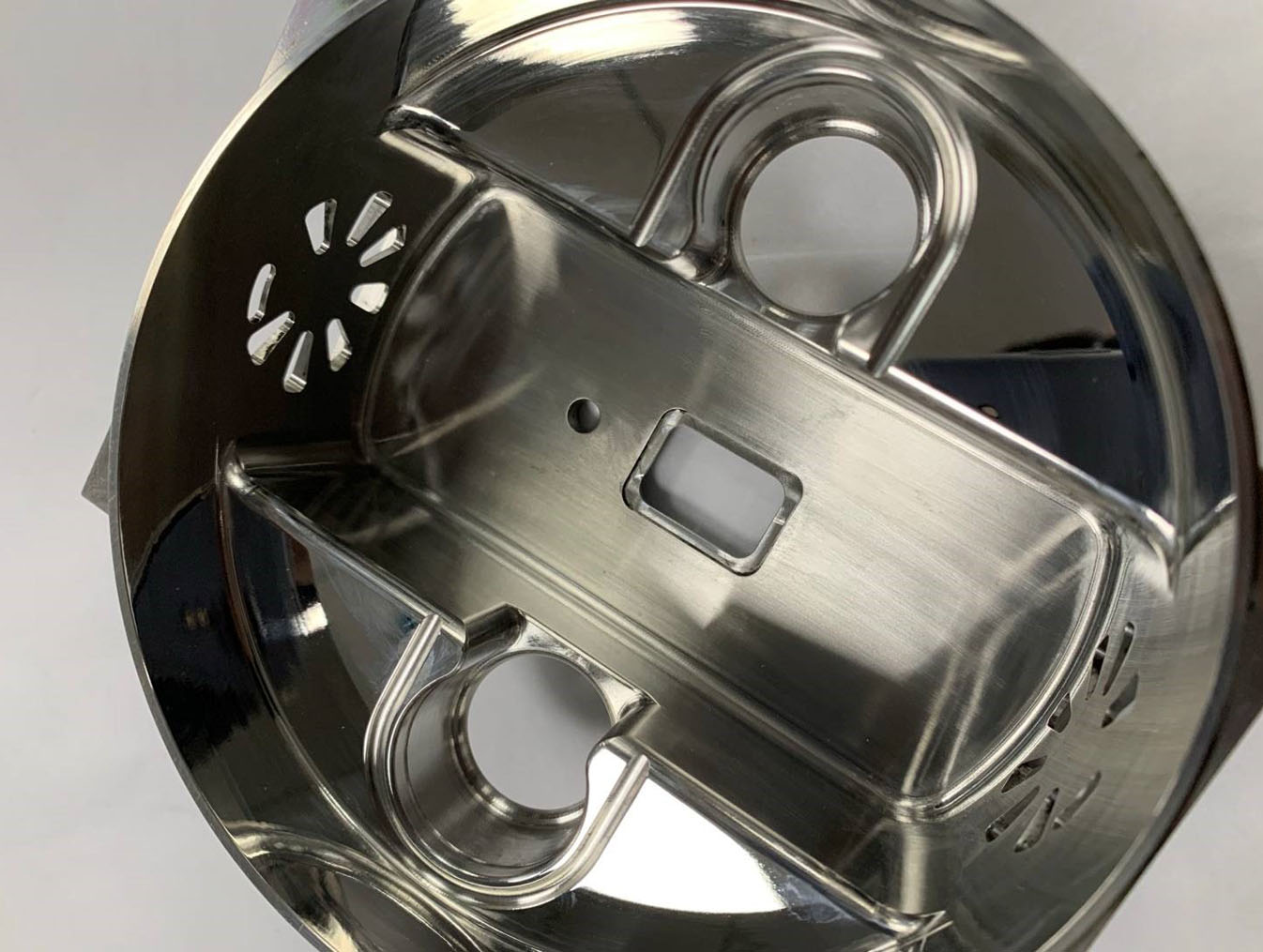

Electropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part, typically stainless steel or similar alloys. The process leaves a shiny, smooth, ultra-clean surface finish.

Corrosion resistance is critical for metal used in a variety of applications where contamination may have a destructive impact during production or during a product’s end use. passivation is a non-electrolytic finishing process used to improve the corrosion and rust resistance of stainless steel components after manufacturing.

Powder coating is a dry finishing process that uses a mixture of finely ground particles of resin and pigment. This cured powder coating is much more durable than paint and more environmentally friendly, too.powder coating lasts an average of three to six times longer than paint. It is resistant to corrosion, heat, impact, abrasion, sunlight, and severe weather. Various finishes are also available, including high and low gloss, metallic, and much more.

What is part marking?

Part marking is a cost-effective way to add logos or custom lettering to your designs. Manufacturers mark parts for many reasons:

To differentiate between similar-looking parts, prevent counterfeiting;

To indicate that a process has been performed or a quality check has been passed, ensure that all materials are quality-assured;

To facilitate assembly;

To link a product or component to the assembly line or machine on which it was produced.

Logos, lettering & Signs

The most common uses is to make it easier to tell the difference between parts that look similar. include letters, logos, signs, color, point a difference between rival brands; appear identical parts, but may function very differently. For example, two springs may appear identical, but a different color stripe is a simple way to tell them load-bearing.

Part tagging

Part tagging involves marking the parts with incremental serial numbers to allow for traceability. include serial numbers, QR codes, and data matrix codes. helps to apply these finishes on custom manufactured parts through their lifecycle.

Our part marking capabilite

Part marking is available for all orders, whether you request to use laser marking or CNC engraving or silk screening. For more information or request a quote, please send us an email.

CNC engraving is an elegant and long-lasting marking method. and looks great on any material with a contrasting surface treatment such as anodized aluminum or layered acrylic. The color of the engraving is typically the natural color of the raw material.

Laser marking is fast and precise. It provides clean lines, durable and maximum precision marking that does not wear over time, commonly used for serial numbers.

Silk screening is an inexpensive option for marking parts. It allows for a wide range of color options, which can be indicated with either a Pantone or RAL number.Silk screening works great on a wide variety of materials, including bare metal or stainless steel.