Sidebar

Description:

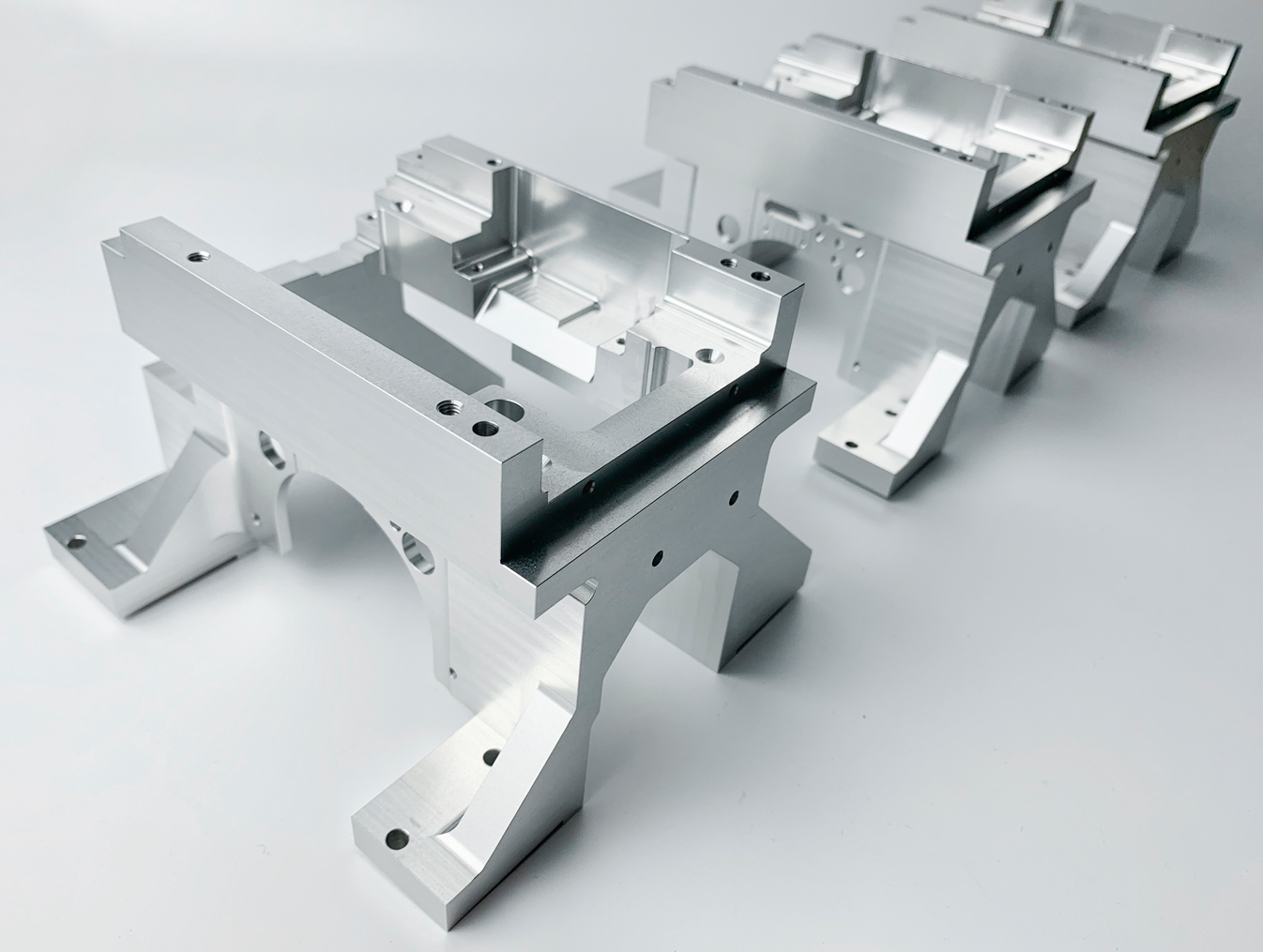

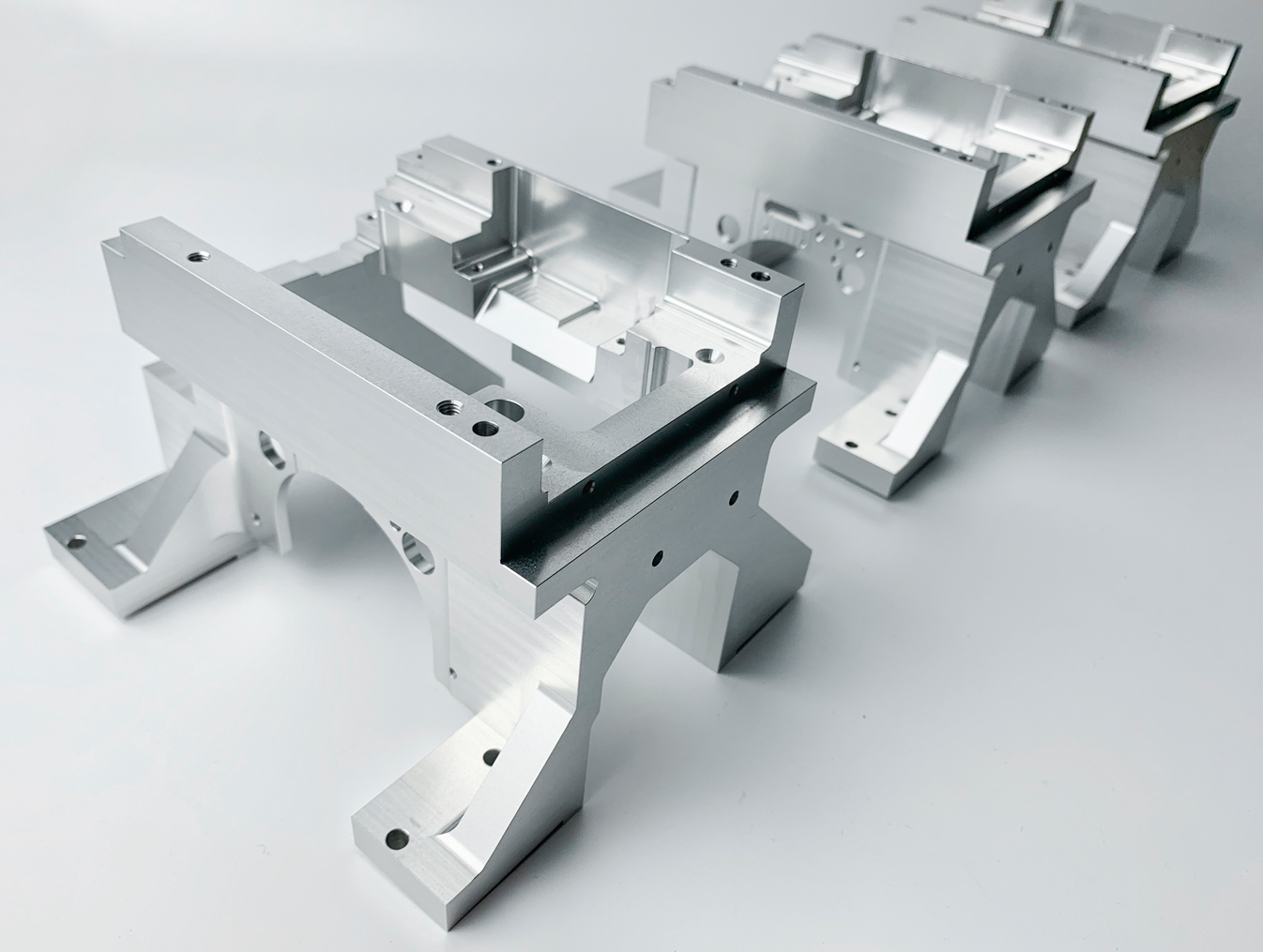

Although 3D printing may be the fashionable face of prototyping, CNC machining remains the better technology for many components.

One of the biggest benefits of using CNC machining to create prototypes is that CNC machined prototypes are made from solid materials, unlike 3D printing. If the part needs to withstand moisture, temperature extremes, contact with chemicals or heavy loads, then it is most likely that CNC machined prototypes will be better than 3D prints.

Whatever you need parts for – perhaps a proof-of-concept prototype, visual model to show backers, usability trials or any other stage in the product development process – CNC machining holds tight tolerances on metals and plastics, as well as being fast and cost-effective. CNC machining is also excellent for low-volume production parts required by machine builders and companies manufacturing small quantities of high-value items.

We are happy to share our many years of prototype machining experience to help you achieve the best results in your projects.We can provide CNC machined prototypes in a range of materials including aluminium, stainless steel, engineering plastics, coppper, brass and other metals.