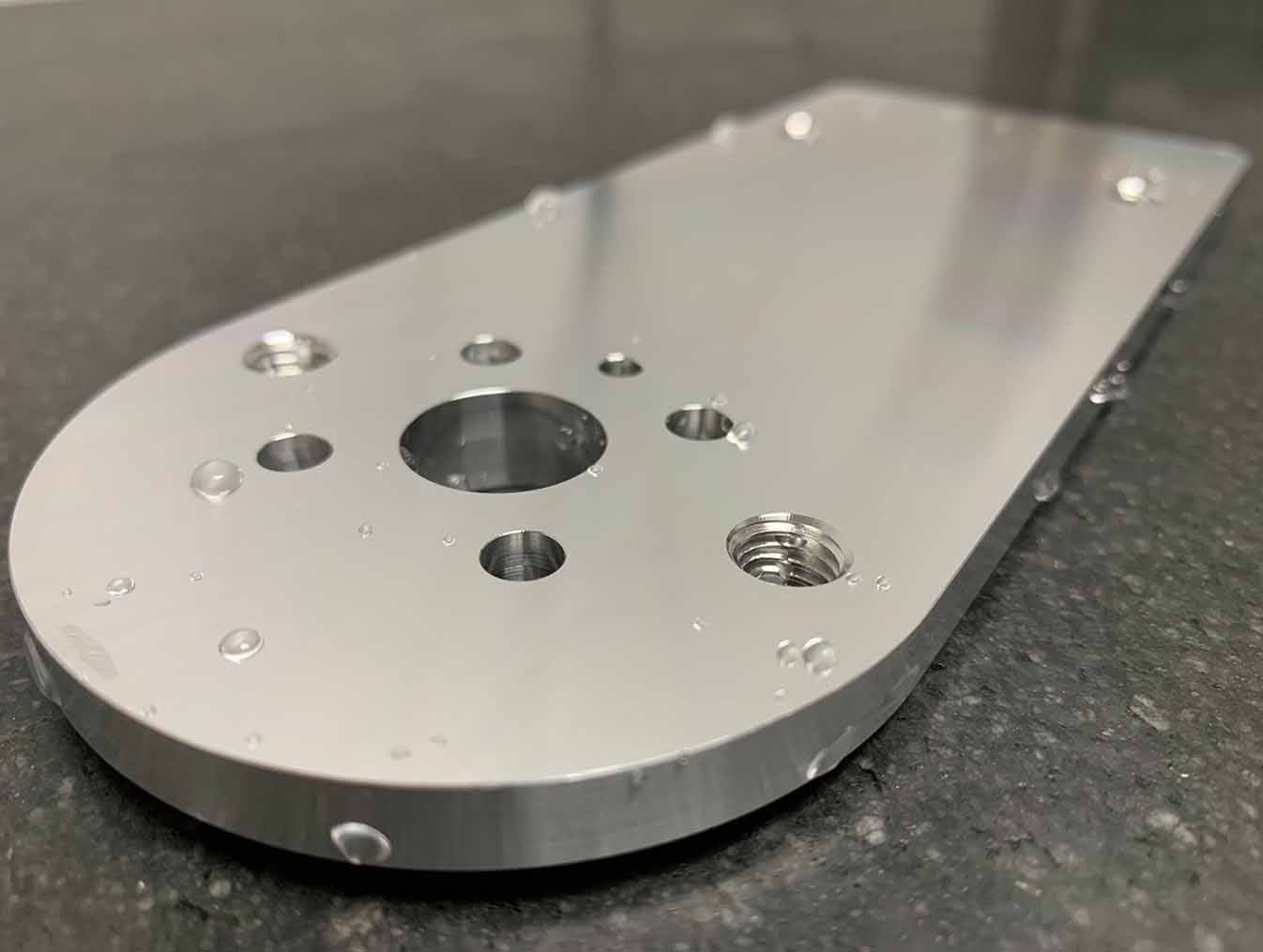

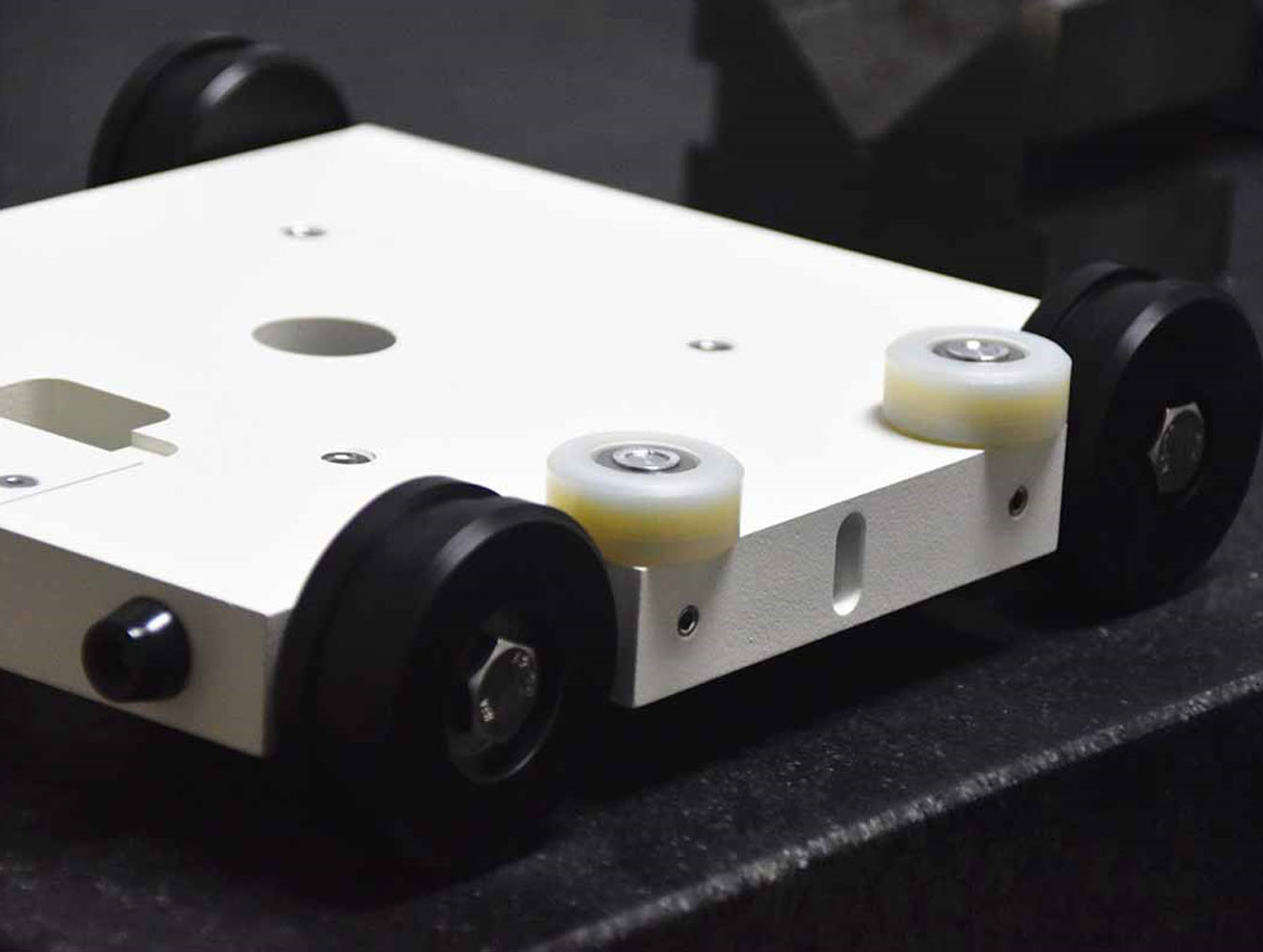

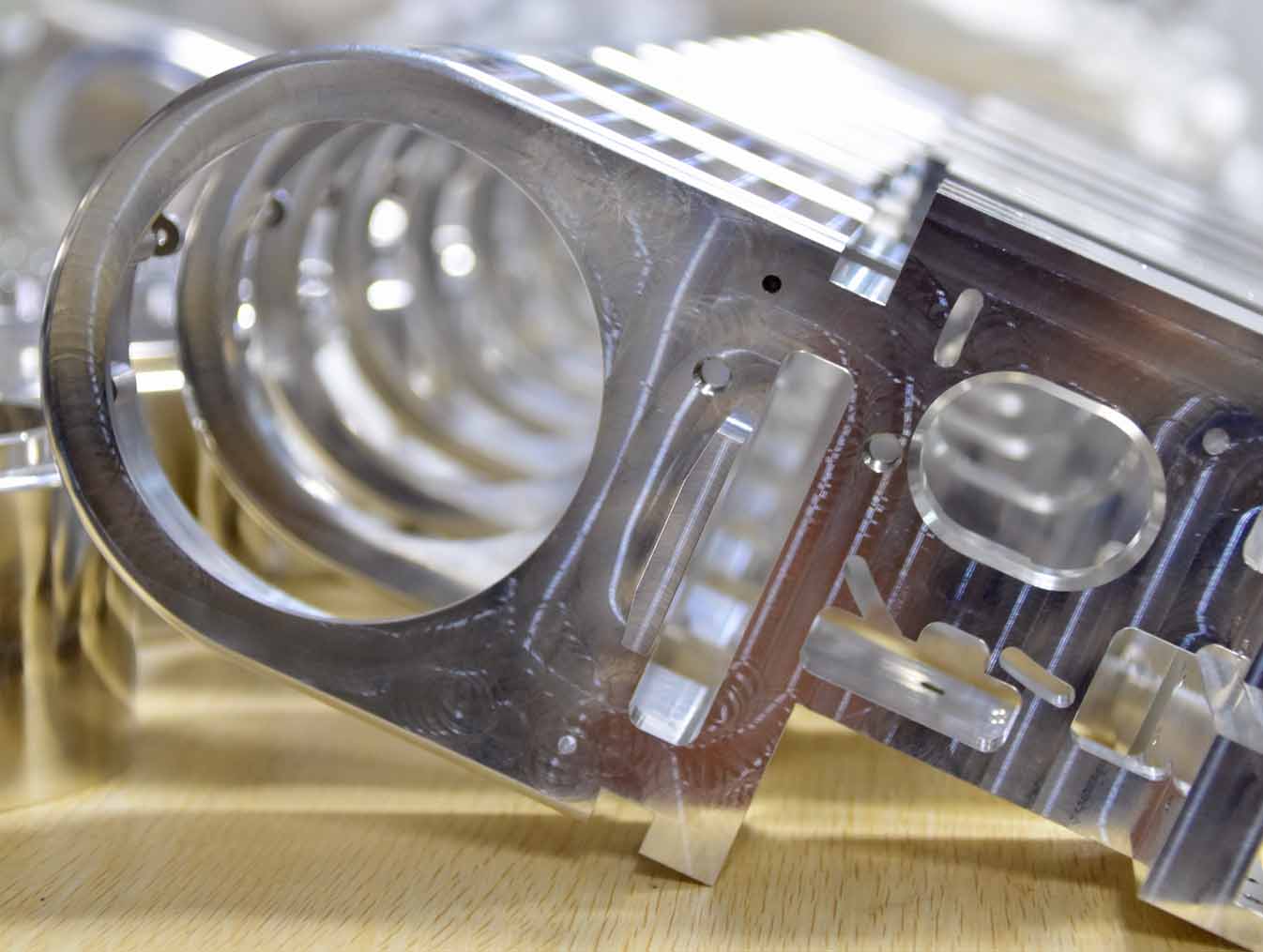

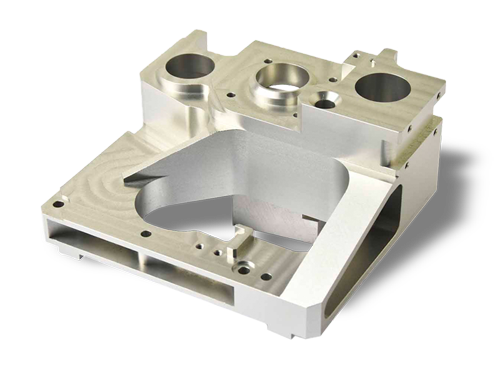

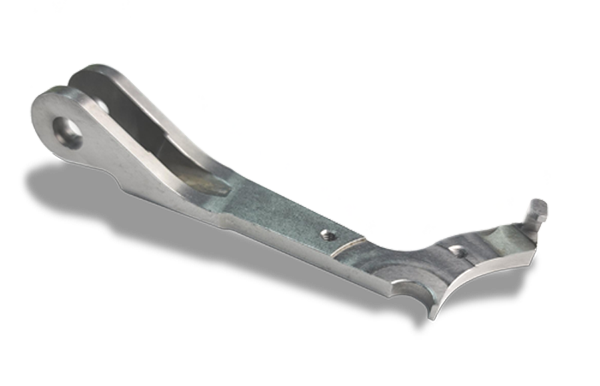

As a professional CNC parts manufacturer, Yadaworks, with a core competency in 3,4&5 axis machining and strong technical knowhow, can support a high level of part complexity and provide exceptional surface finishes for both complex prototypes and low-volume production.

Always ensure you get CNC machined parts you need on time and with high quality. Mechanical work can become easier for you through our following CNC machining services:

CNC Milling

CNC Turning

Prototype Machining

Insert installation

Masking & 2nd Machining

Part Marking

Available Material For CNC Machining

Our shop can machine virtually any engineering material, including plastics, metals, alloys.

Here is a list of our standard CNC machining materials available

Aluminum is a highly ductile metal, corrosion resistant, light weight and making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

We offer 5-axis and 3-axis vertical milling of blocks in aluminum, as well as CNC turning of aluminum round bar stock.With this service we can produce a wide variety of machined parts and enclosures.

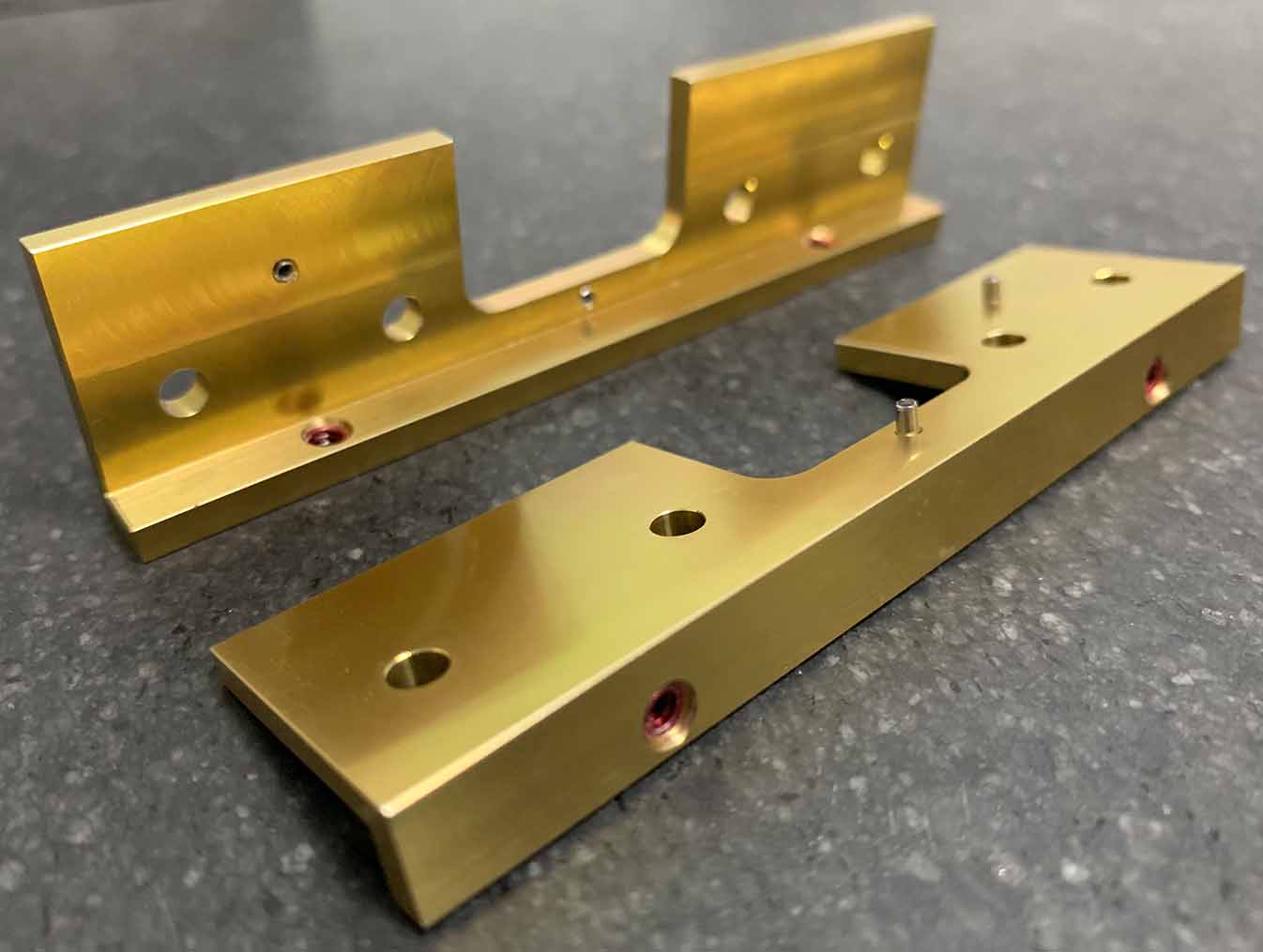

Brass has excellent electrical conductivity along with exceptional formability, and is thus ideally suited for electrical and electronic applications. It is low friction, and has a golden (brass) appearance. It is commonly used in parts that need a large load..

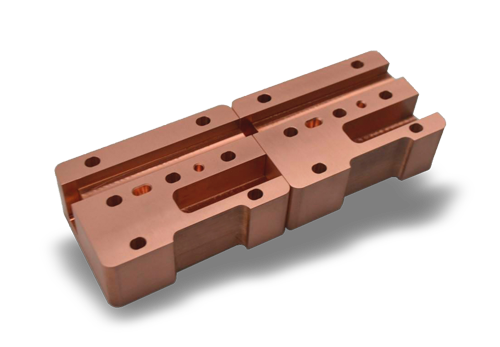

Copper has very high conductivity along with exceptional formability, It is also highly ductile, corrosion resistant and can be easily welded.and is thus ideally suited for electrical and electronic applications..

Plastic is one of the most commonly used materials in the world because of its strong corrosion resistance, durable, waterproof, light weight, low cost and easy processing.

Some plastic, like Acrylic sheets, offer properties similar to glass such as clarity, brilliance and translucence, but is lighter and has better impact resistance.and used on a regular basis with enclosure design, to provide clear windows into cases.

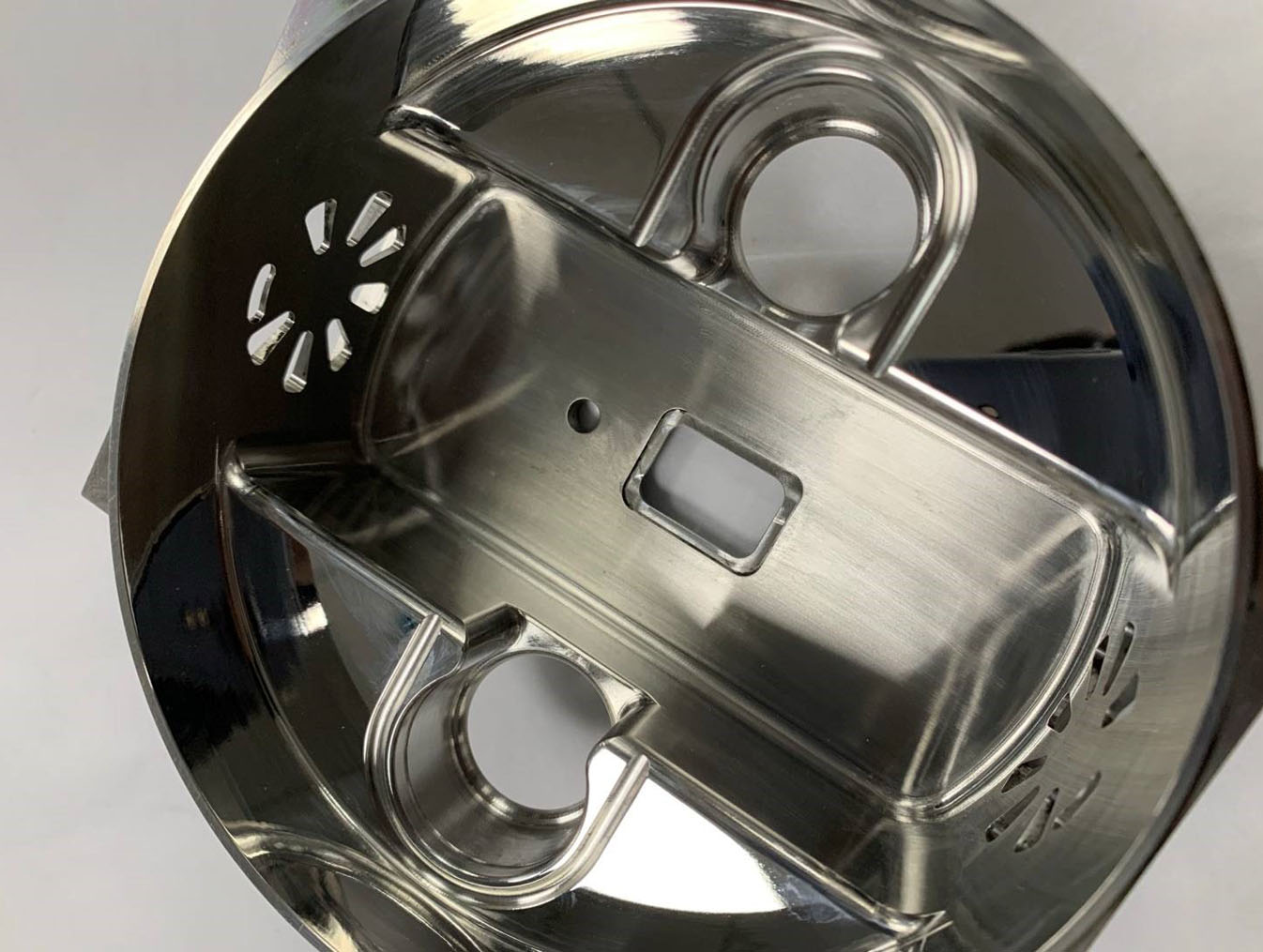

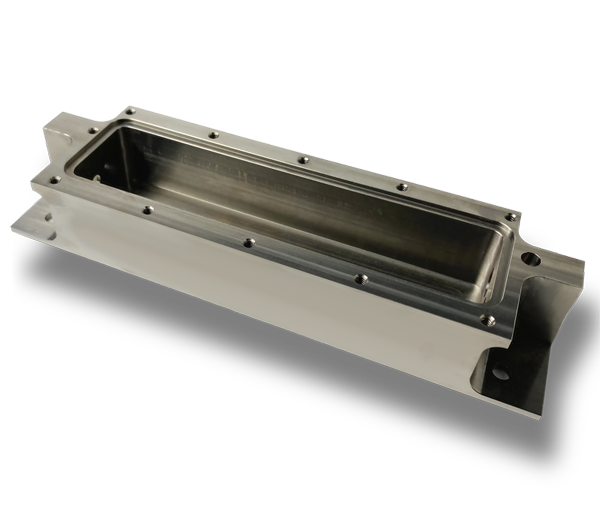

Stainless steel has Same stiffness advantage of steel yet even higher strength.features a high-temperature resistant, with good oxidation resistance and corrosion resistance. Premium solution to corrosion resistance.It is widely used in machine parts, contruction industry parts, etc.

Steel is an iron alloy, meaning it’s primarily composed of iron and combined with one or more alloying metals to produce new materials with unique properties. There are four main classifications:

Carbon steel / Stainless steel Alloy steel / Tool steel

Compared with ordinary carbon steel, special steel has better strength and toughness, physical properties, chemical properties, biocompatibility and technological properties.

In the world of CNC machining, and even manufacturing in general, titanium seems to be held in the highest of regards.Titanium is a hard metal, but the best steels are generally stronger than titanium alloys.but titanium has the ability to flex or bow repeatedly in CNC conditions.Titanium alloy is widely used in medical, automobile industry because of its light weight, high strength and good corrosion resistance.

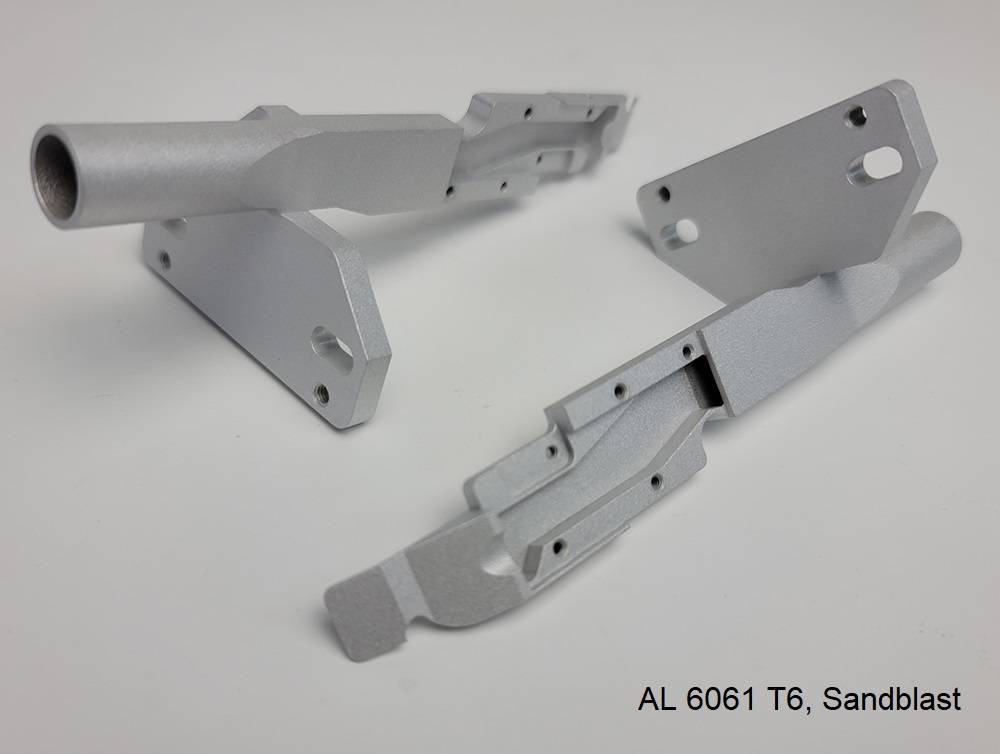

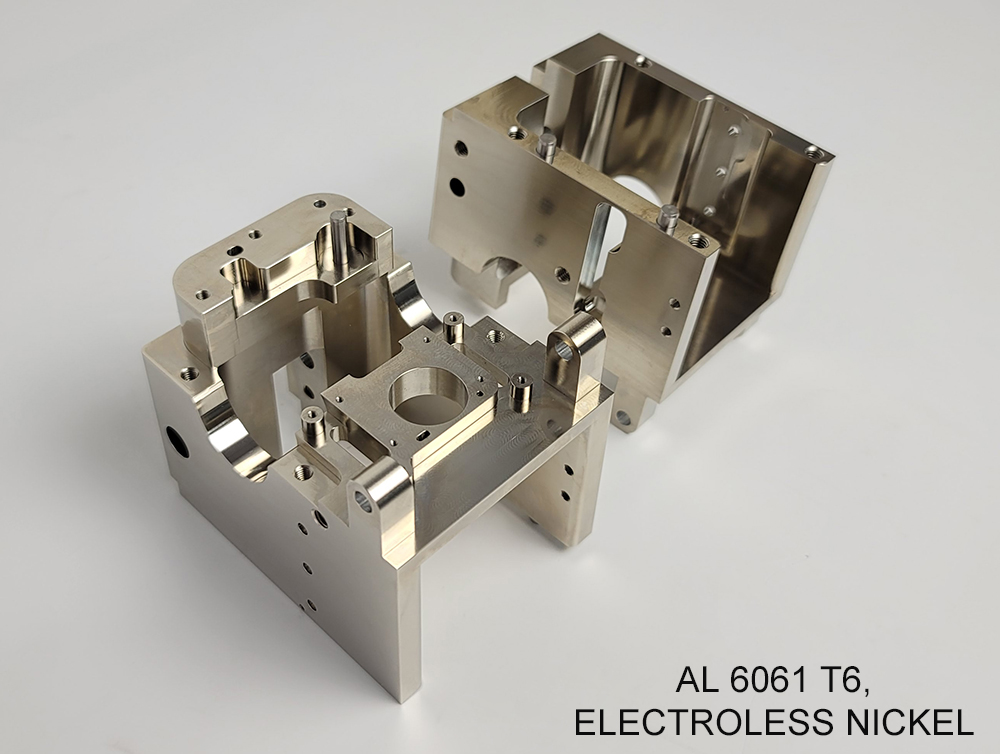

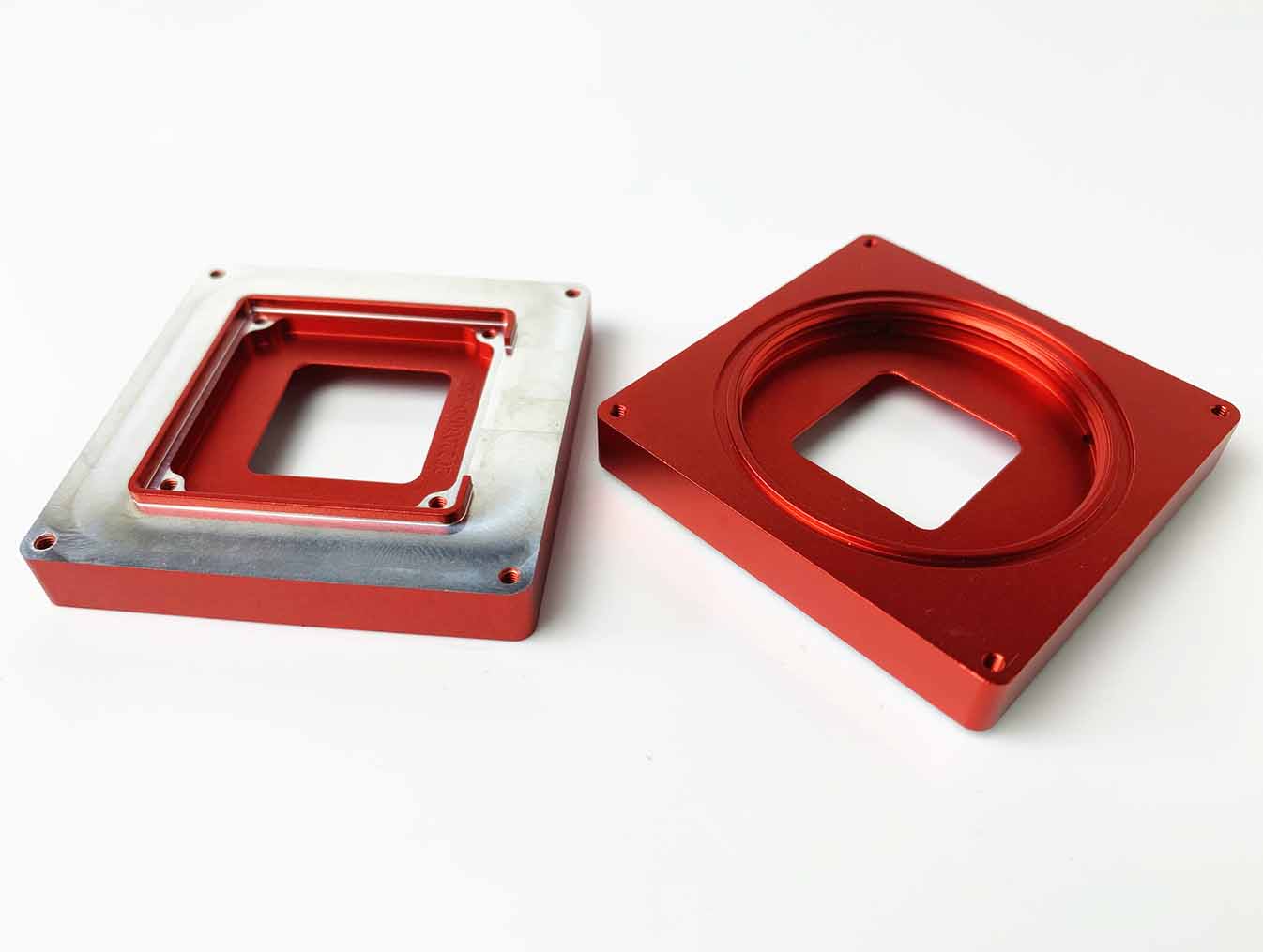

Available Surface Finishes of Our CNC Machining Services

Surface finishes are applied after machining and can change the appearance, surface roughness,

hardness and chemical resistance of the produced parts. At Yadaworks, in Addition to Precision,

you can get CNC parts with nice machined surface and more option:

CNC Machining FAQs

Get the support you need on CNC machining and engineering information by reading the FAQ here.

The maximum size we are able to mill in a single setup is 1100mm x 650mm x 580mm. The maximum size bar stock that we are able to lathe in a single setup is 800mm x 100mm.

CNC, or computer numerical control machining, is a subtractive manufacturing method that leverages a combination of computerized controls and machine tools to remove layers from a solid block of material. The desired cuts in the metal are programmed according to corresponding tools and machinery, which perform the machining task in an automated fashion.

Rough machining is to machine (work) approximately to size usually by taking heavy cuts with the object chiefly of removing excess metal rather than of obtaining a correct size and finish.and designed for roughing down billets, plates, castings or forgings, by hogging out large amounts of material.

We specify a standard dimensional tolerance of +/-0.004" for CNC machined parts. However, it is possible to achieve a tighter tolerances up to +/-0.0002" on our lathes, 3-axis mills and 5-axis mills. If you require a tighter tolerance, please contact us.

Due to the spinning motion produced by the CNC milling machine's cutter, the surface finish of CNC machined parts will have visible toolmarks. If you require a smooth, unblemished finish to your part, we recommend choosing a secondary finish.