Sidebar

Description:

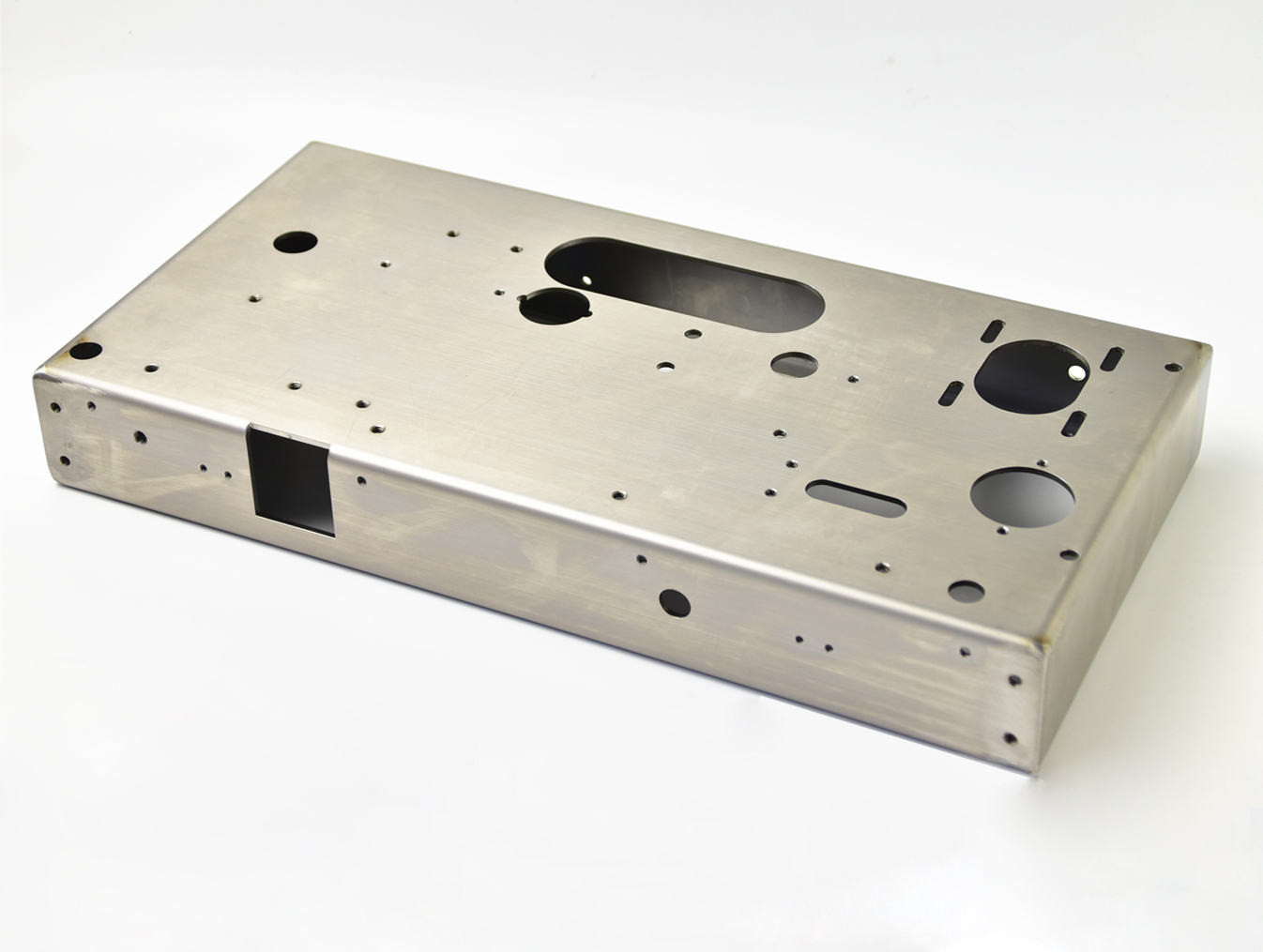

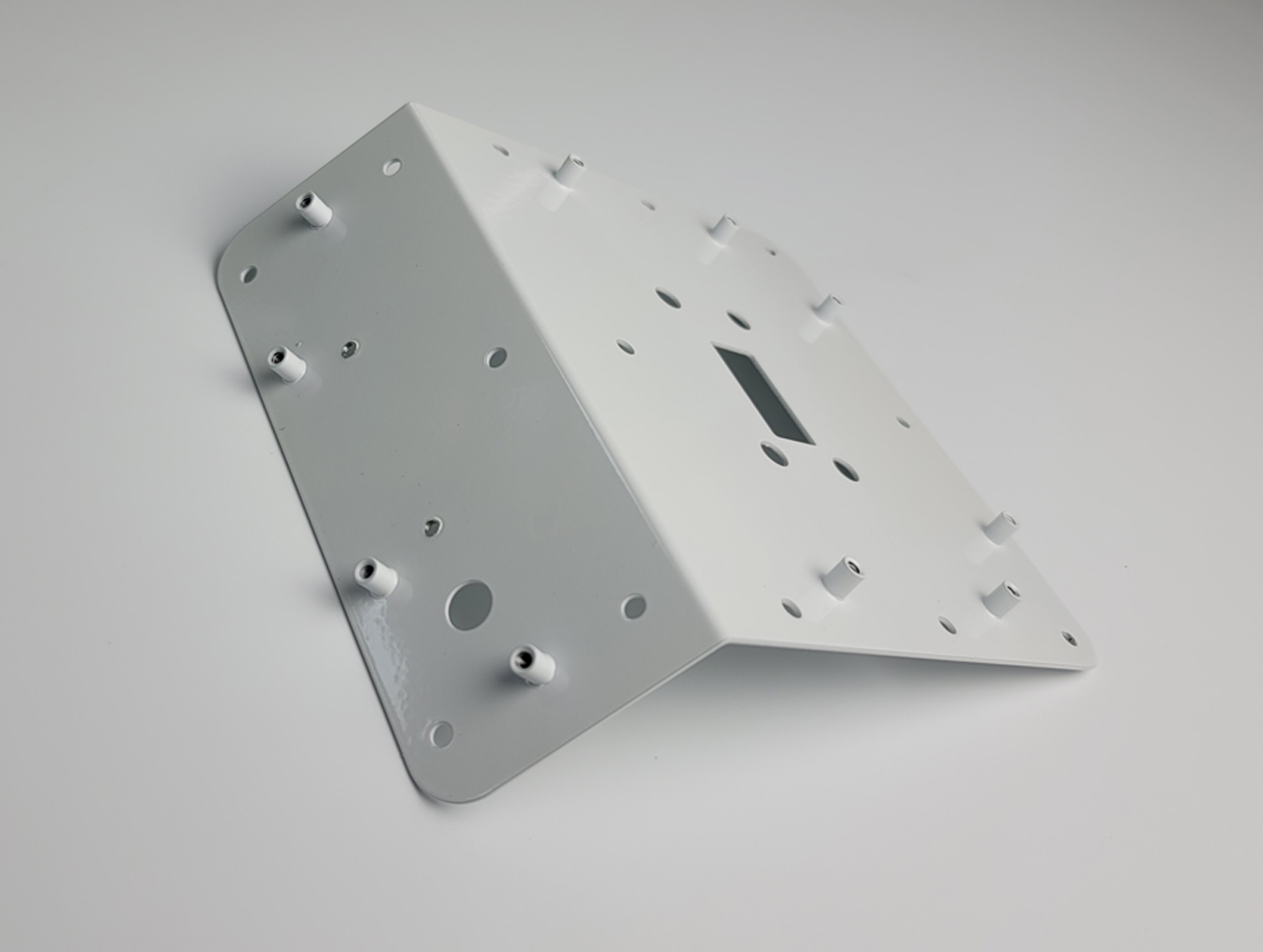

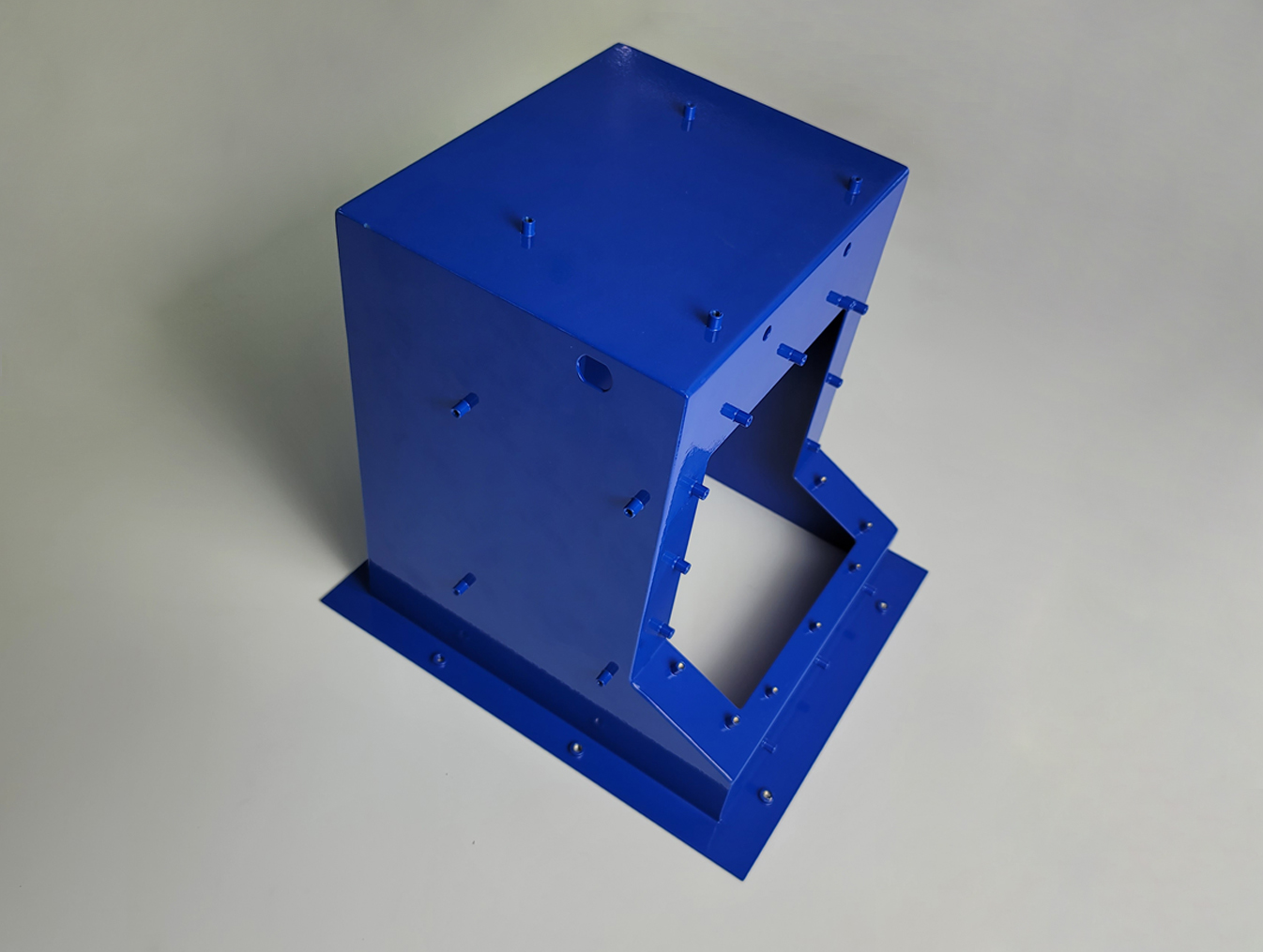

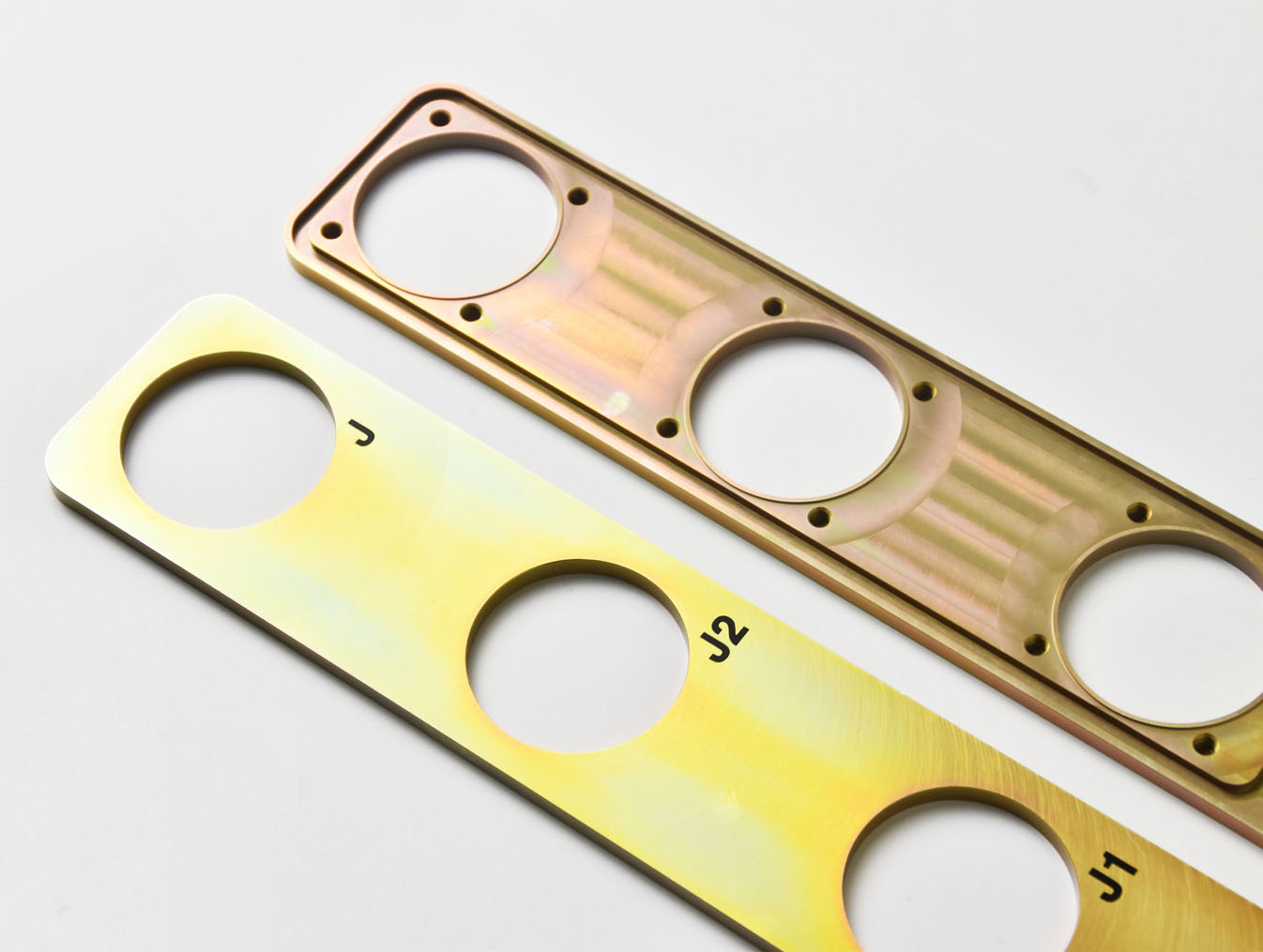

Hybrid enclosure is a combination process of extrusions, sheet metal top and bottom, and custom machined panels and body. Extrusion, Sheet metal and CNC machining processes have unique strengths and weaknesses attributed to both. When combined, the advantages of one balances the weaknesses of the other, resulting in structures with maximum strength and resiliency.

Hybrid enclosures are ideal candidates for this hybrid process because of their unique requirements: The machined body made of blocks can provide durable and long-lasting housing. while, you can save your money through using extrusions and sheet metal.without wasted time, materials or labor, driving costs down in the process.

Although this hybrid process has the advantages of cost and performance, it has to increase the difficulty on precision, surface finish, color match, and assembly. With Yadaworks, you’ll have confidence your product will meet all of your spec requirements and the advantages of hybrid construction are no longer out of reach.